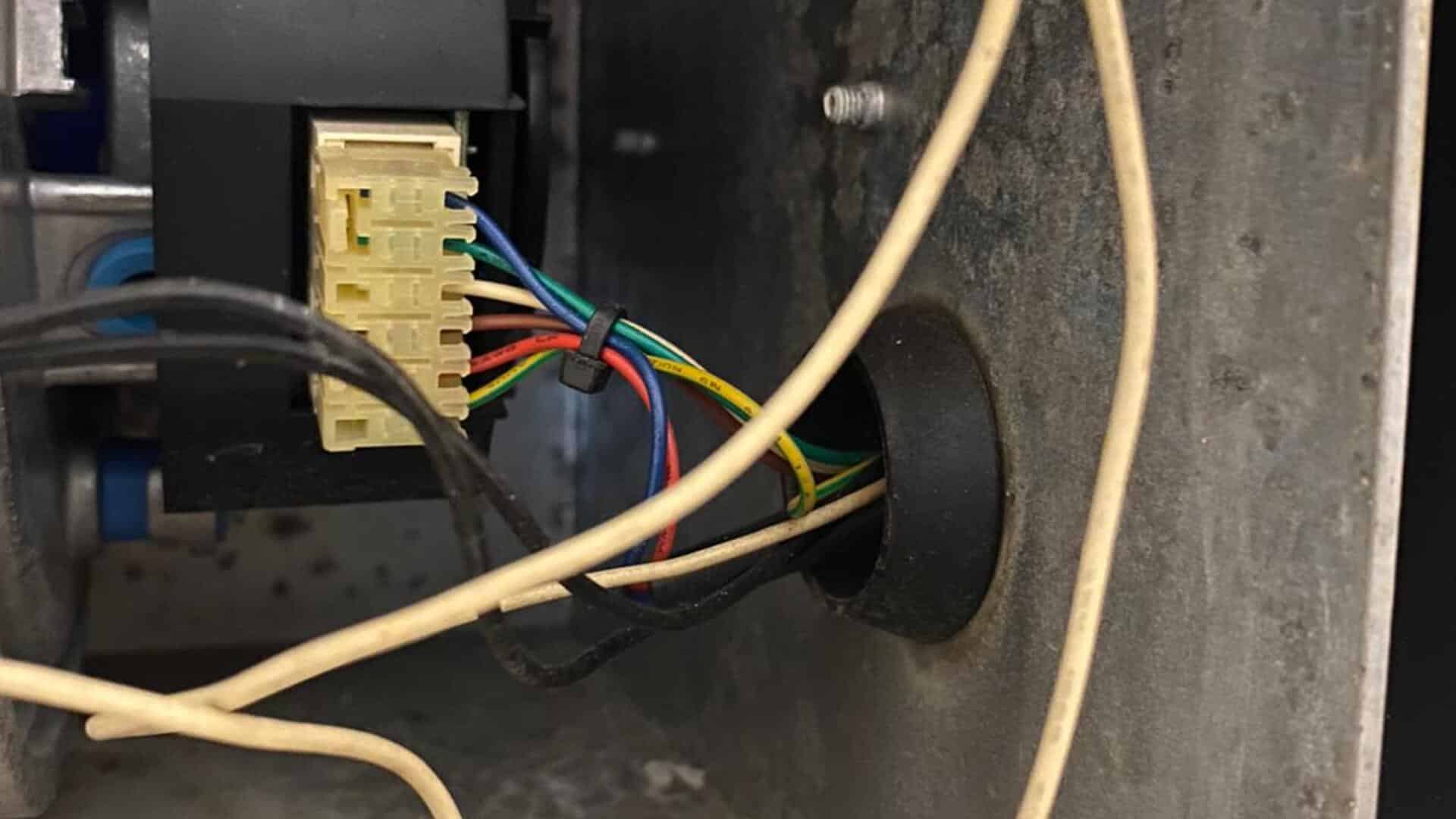

Upon inspection, the engineer found significantly more than a simple water leak. Systematic examination of the boiler revealed multiple issues affecting safe operation:

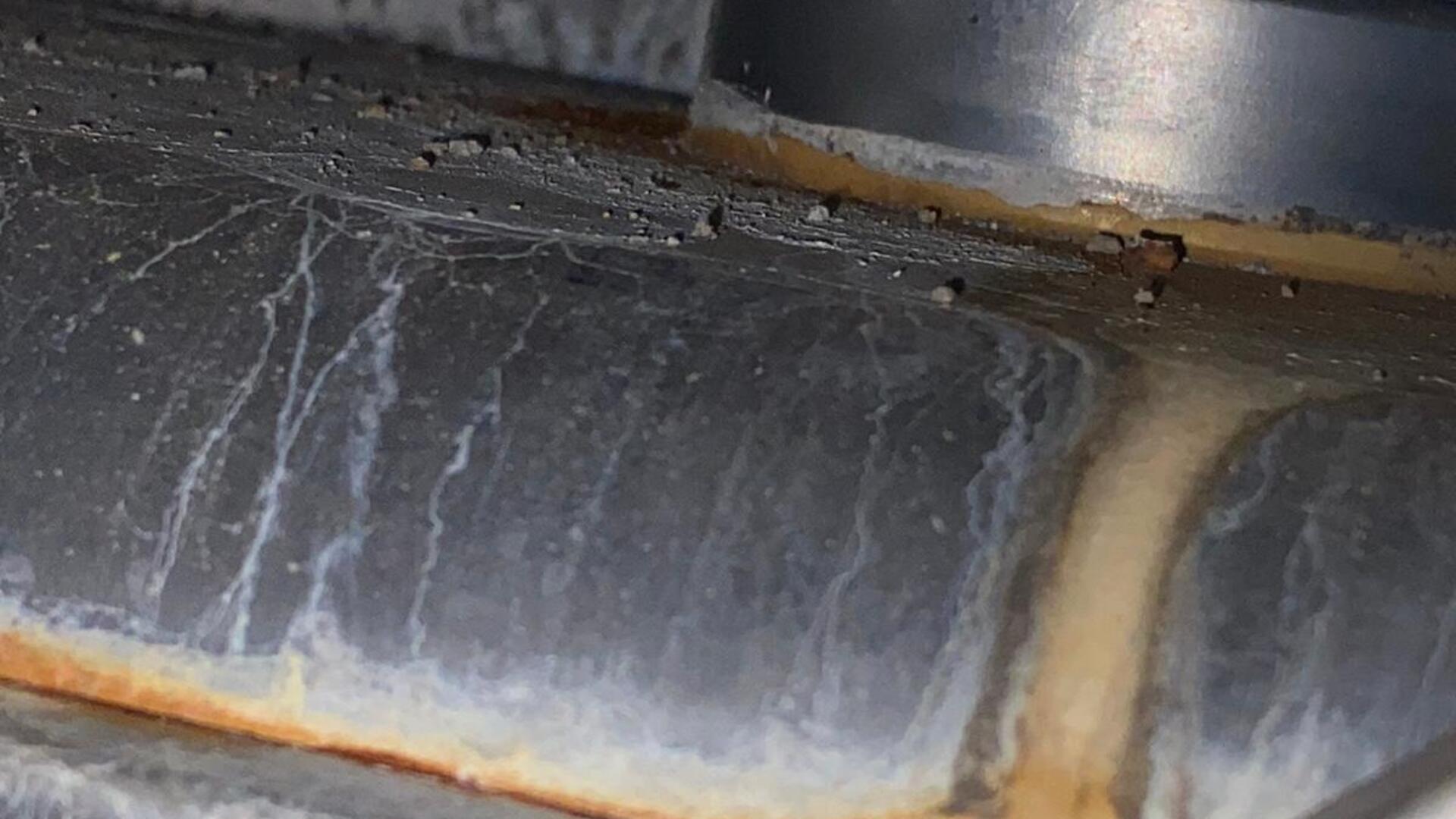

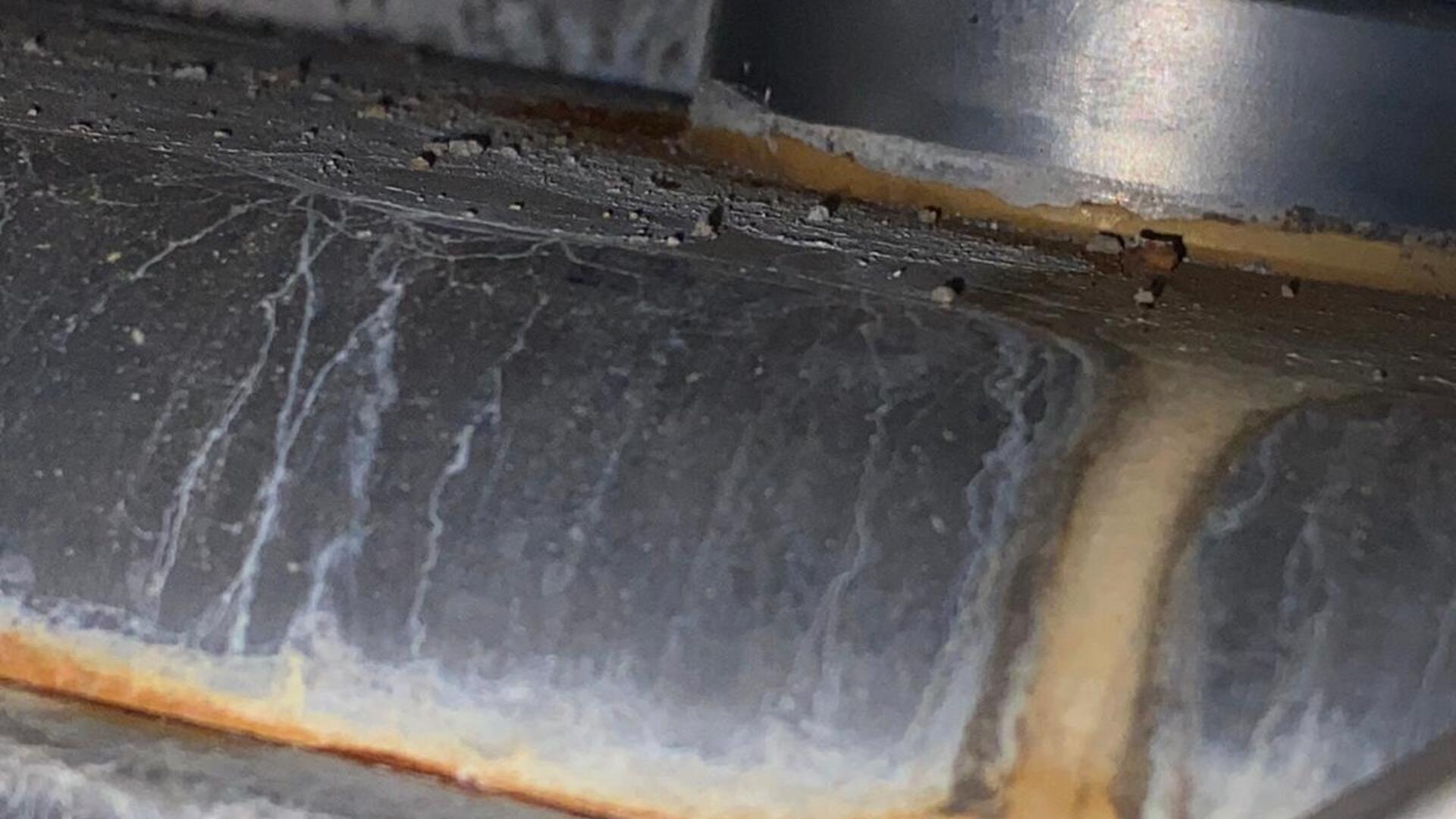

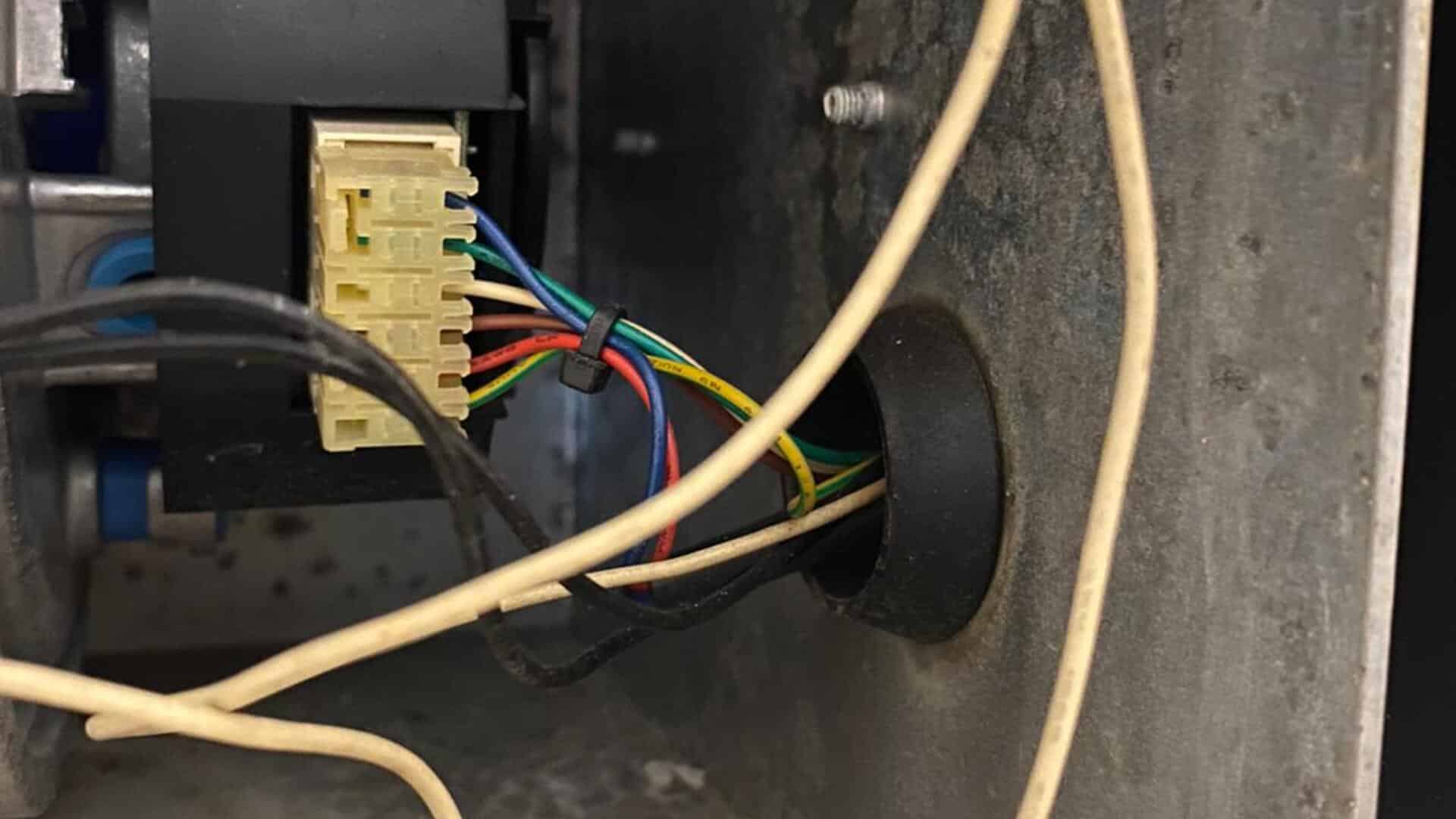

Flue Seal Failure: The seals around the flue connection were leaking. Flue seals are critical safety components—they ensure that combustion products are properly directed out of the property rather than escaping into the living space.

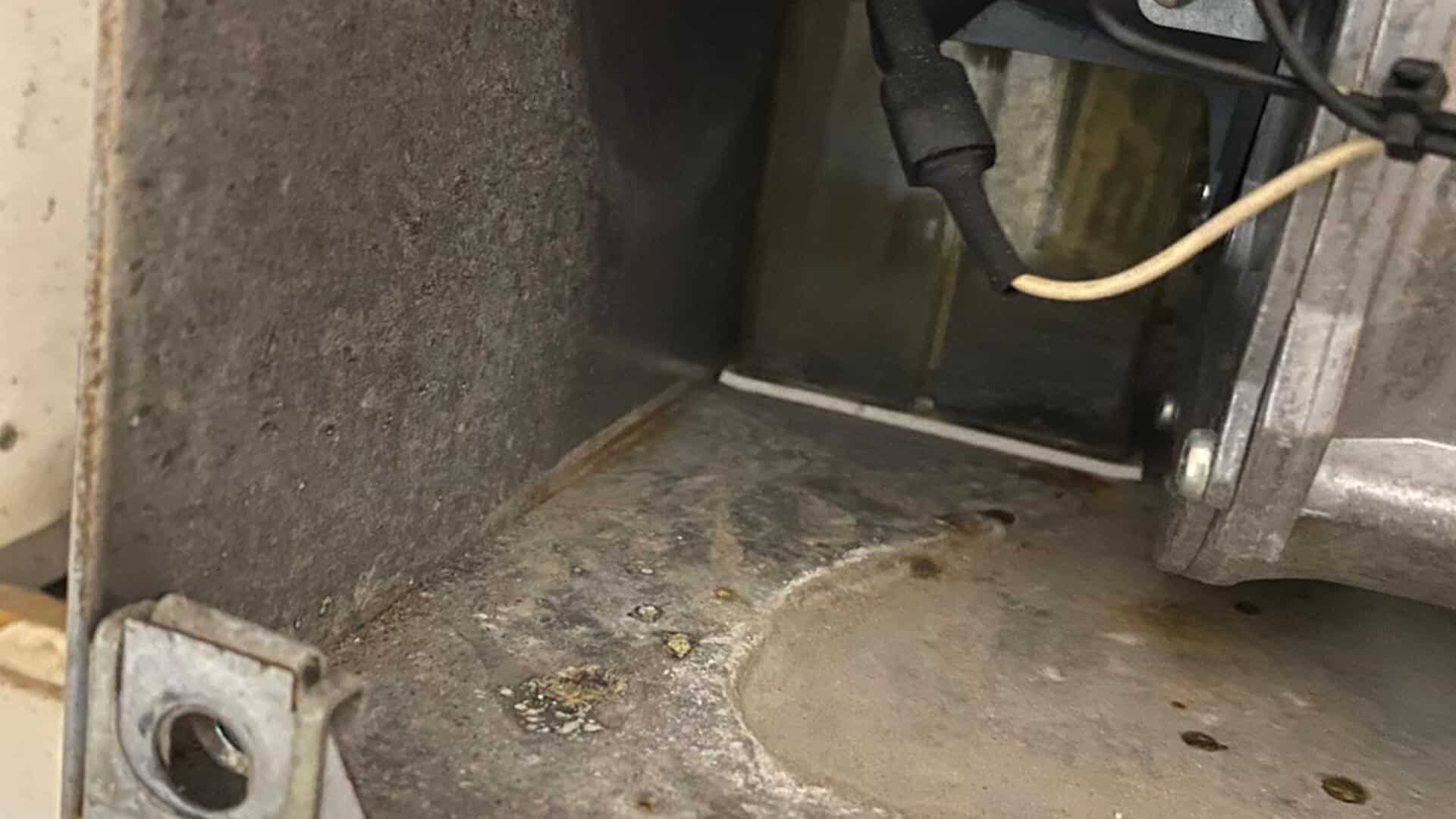

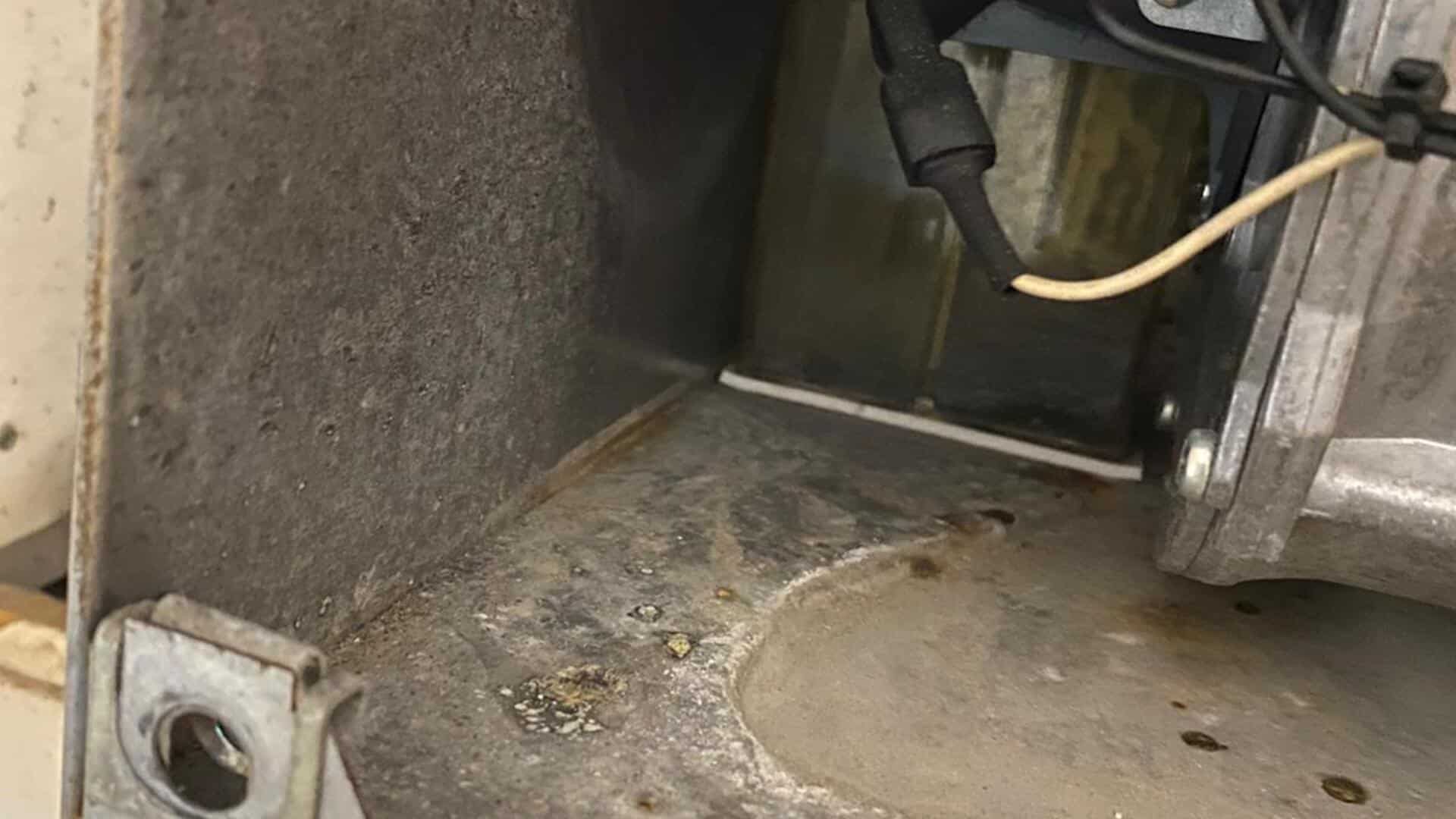

Active Water Leak: Water was observed leaking while the boiler was running. Attempts were made to recreate the leak during the visit to identify the precise source.

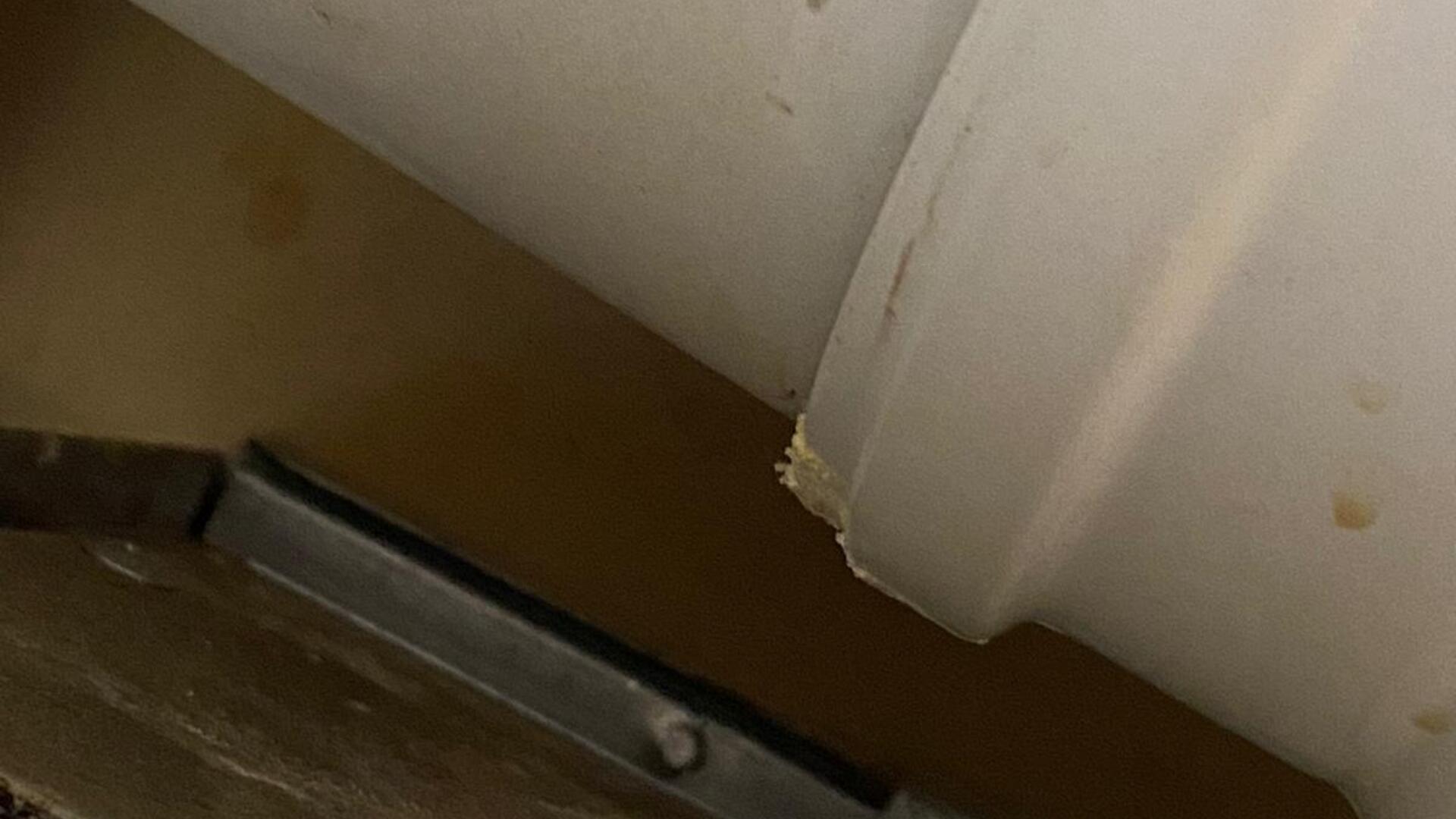

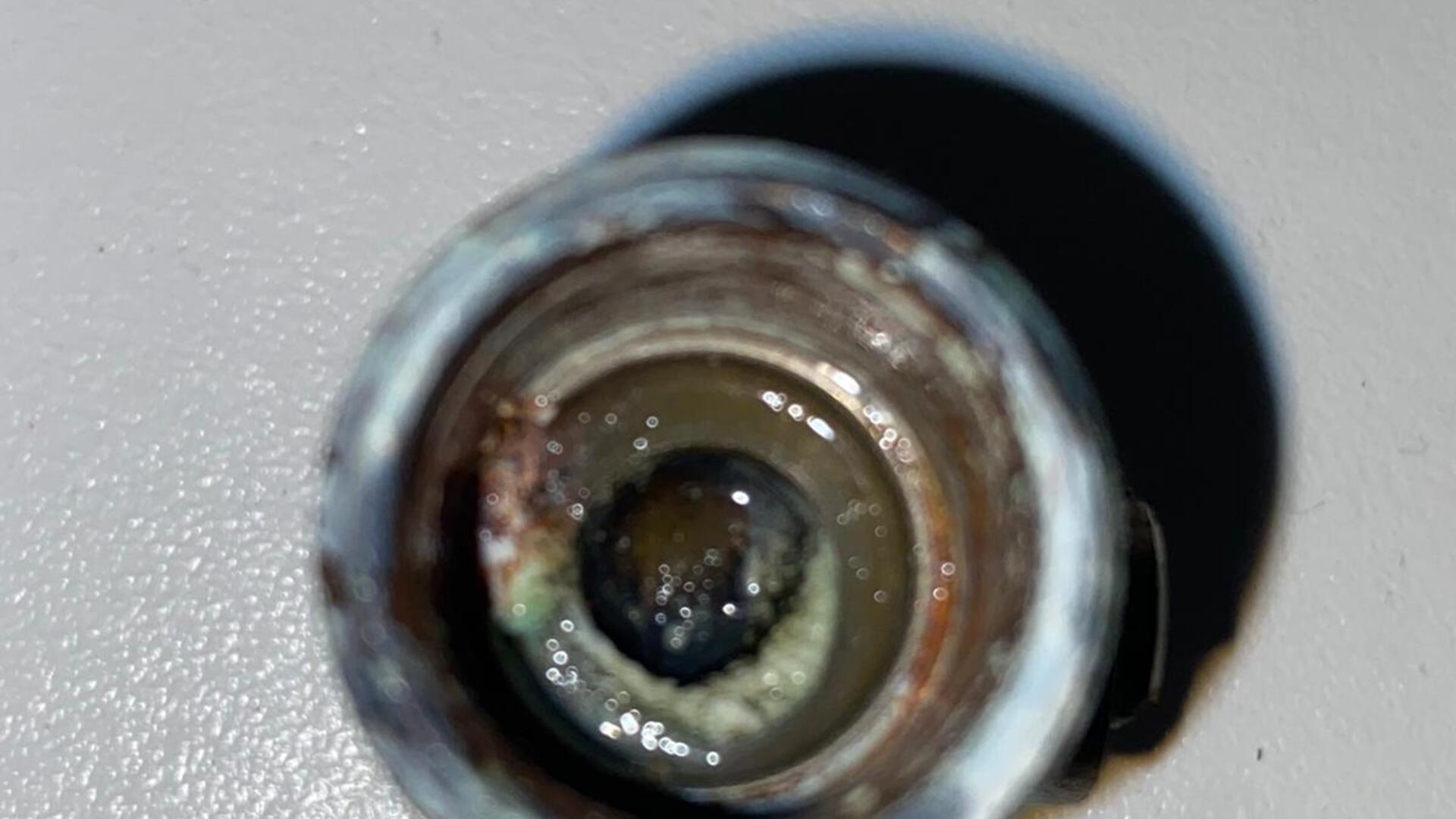

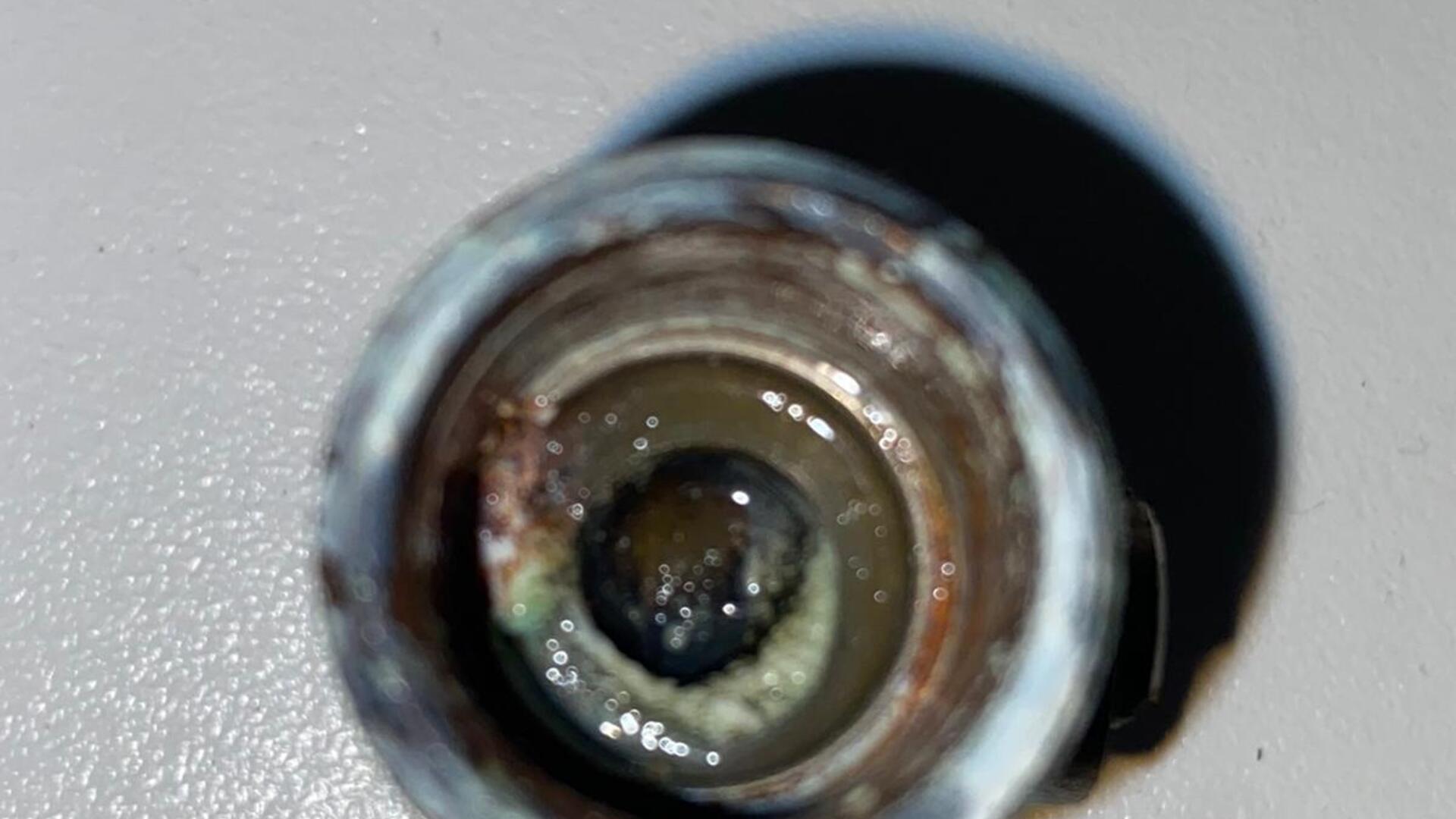

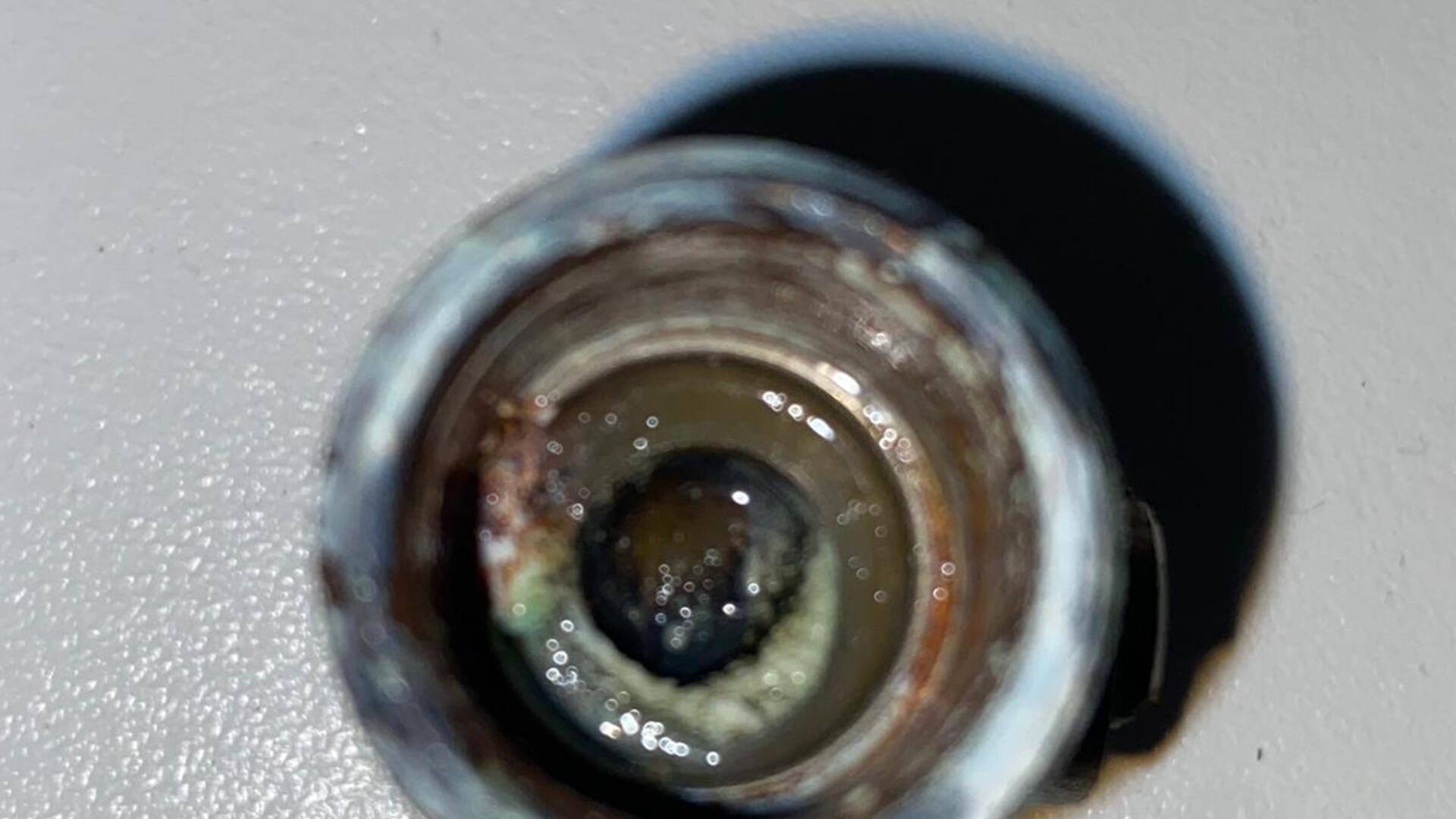

Cracked Condensate Trap: The most likely source of the water leak was identified as the condensate trap, which appeared to be cracked. Condensing boilers produce acidic condensate as a byproduct of their high-efficiency operation; this condensate must be safely routed to the drainage system.

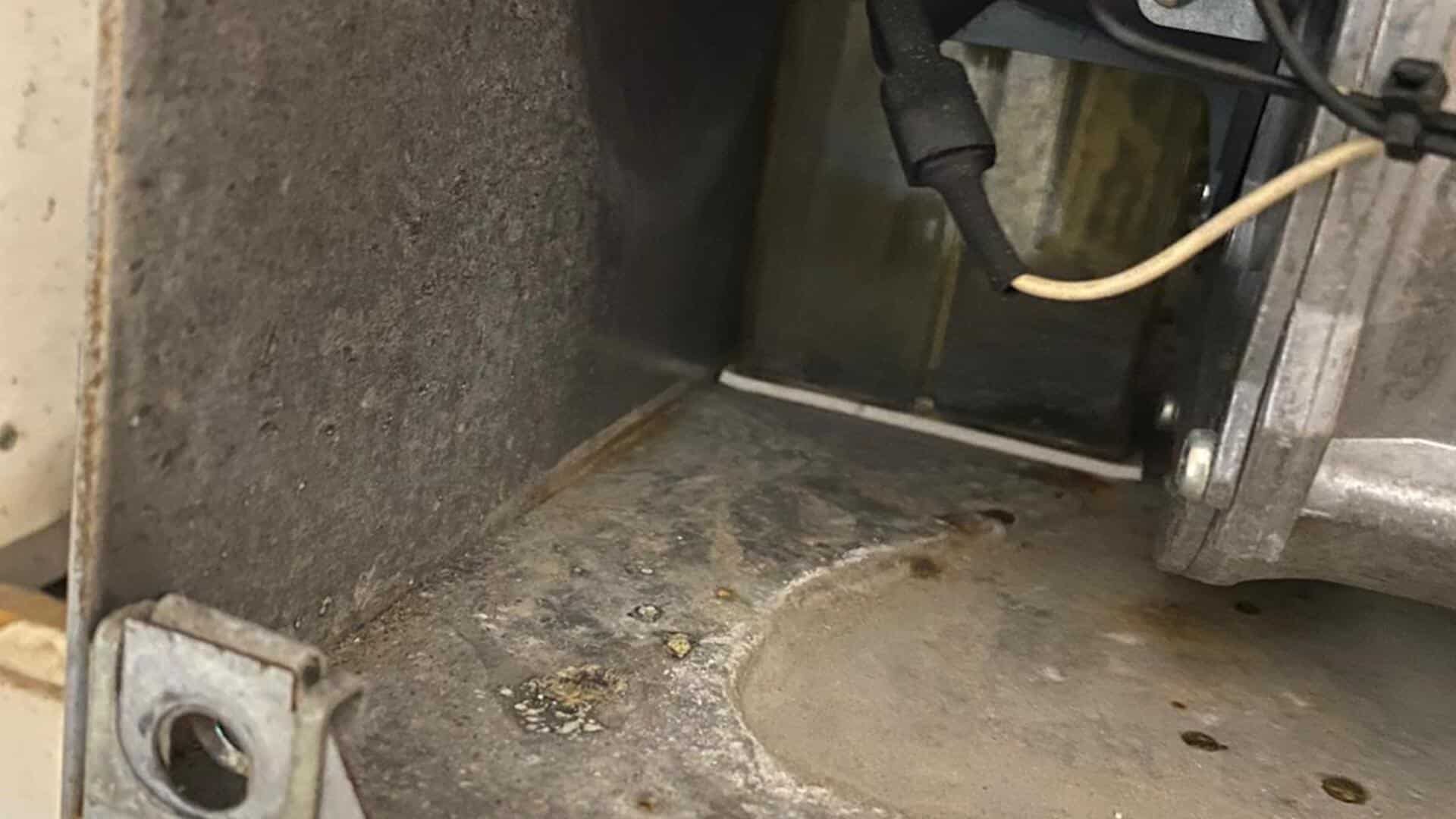

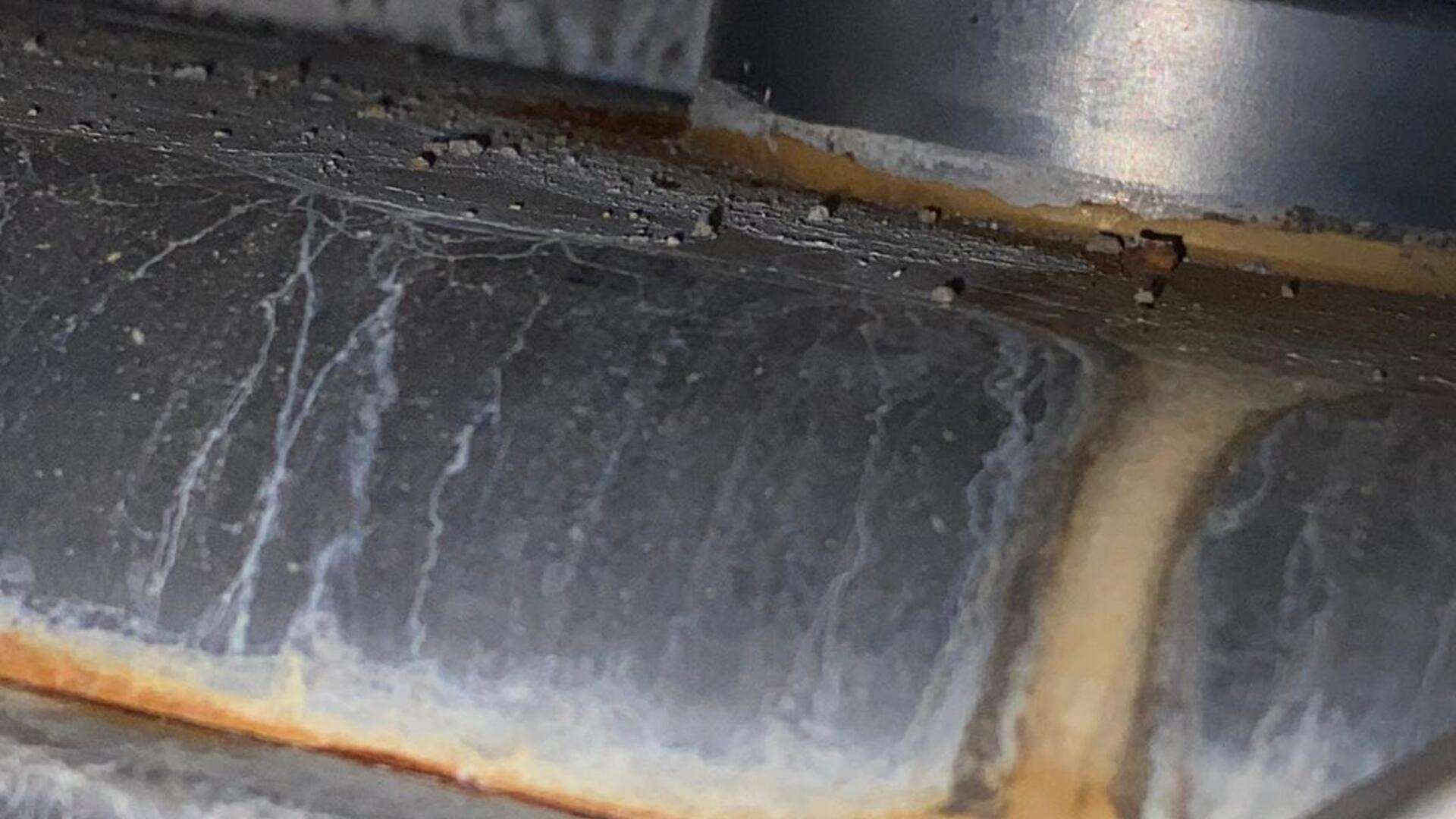

Internal Corrosion: The suspected cracked condensate trap aligned with internal corrosion observed within the boiler. Where condensate escapes its intended pathway, it causes rapid corrosion of internal components.

Casing Seal Failure: The boiler casing was not forming a proper seal, allowing internal leakage and potentially compromising the combustion chamber’s integrity.