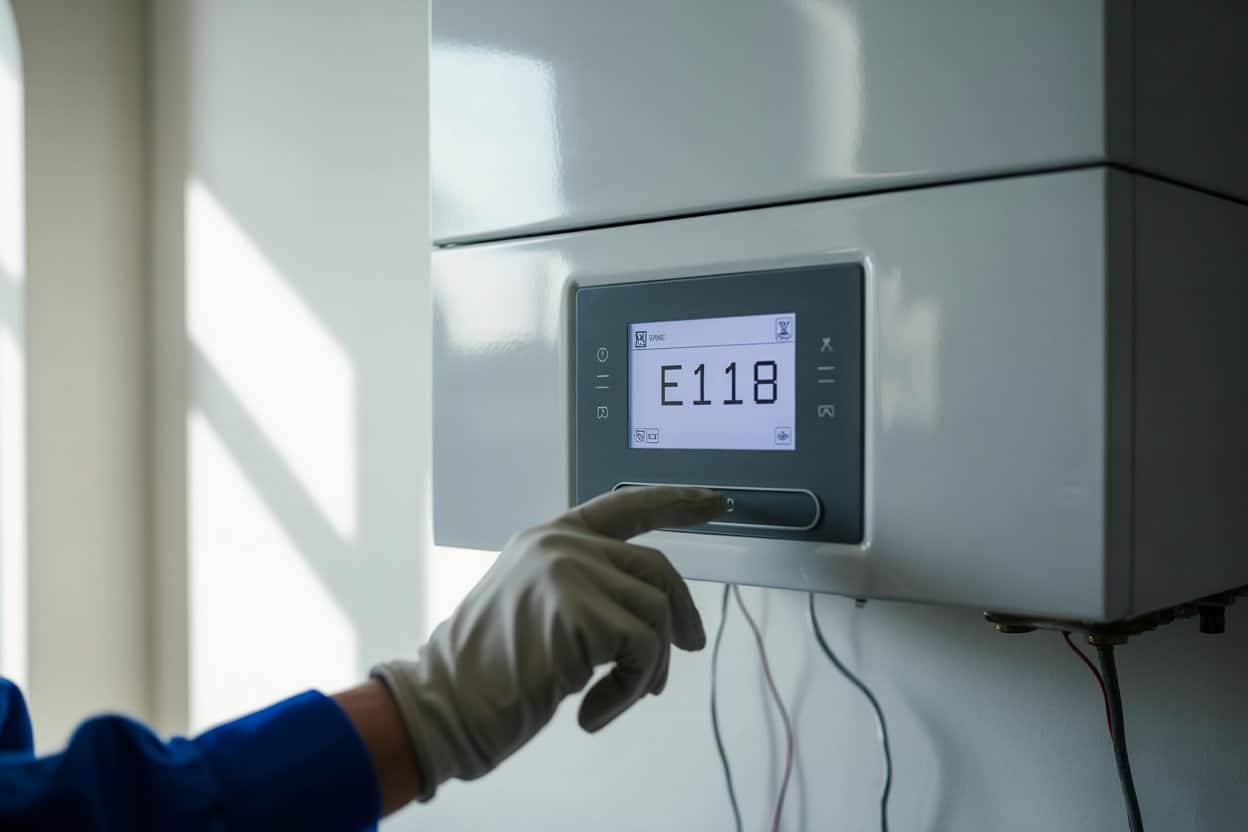

Fault diagnosis error codes function as the cornerstone of modern property maintenance by providing a systematic method for detecting and diagnosing electrical irregularities. They are produced by advanced digital instruments that monitor critical parameters, such as voltage and current, and compare readings against preset safety thresholds. The resulting codes help maintenance technicians determine whether an issue is minor or requires immediate remediation, thereby safeguarding both property and occupant safety.

Etymology or Name Origin

The term “fault” is rooted in the Latin verb fallere, meaning to deceive or mislead, reflecting the inherent notion of a deviation from expected performance in electrical systems. “Diagnosis,” derived from the Greek diágnōsis (διάγνωσις), implies a detailed analysis or discernment of a problem’s nature. Meanwhile, “error code” describes the method of encoding specific failure conditions in a readable format for technological interpretation. This combination of terms emerged as electrical systems became more complex and the need for systematic, automated diagnostics grew imperative to maintain operational integrity.

Overview and Context

Definition and Scope

A fault diagnosis error code is defined as the encoded output generated by diagnostic systems when monitored electrical parameters deviate from established norms. These systems regularly assess the condition of circuits, appliances, and installations. When deviations—such as unexpected voltage spikes, current imbalances, or thermal anomalies—are detected, an error code is produced. The scope of these codes encompasses a wide range of potential electrical issues, from transient glitches to persistent faults that could compromise system safety and efficiency.

Conceptual Framework

At the core of fault diagnosis is the principle of continuous monitoring combined with systematic comparison against expected values. Diagnostic tools employ sensors and microprocessors that collect and interpret data in real time. The process includes:

- Data Collection: Instruments such as digital multimeters and oscilloscopes gather quantitative measurements.

- Signal Analysis: Advanced algorithms process these measurements, filtering noise and assessing deviations.

- Code Generation: When anomalies are detected, the system generates a specific error code that encapsulates the type and severity of the fault.

This framework helps property managers maintain system integrity, ensuring that maintenance actions are both timely and appropriately scaled to the detected problem.

History

Origins in Early Electrical Systems

The practice of diagnosing faults in electrical systems can be traced back to the early days of industrial electrification when technicians relied on manual measurements and visual inspections. Initially, the detection of errors involved rudimentary instruments like analogue metres and basic circuit testers. In this period, much of fault diagnosis was based on the intuition and experience of skilled electricians, who would sometimes rely on audible cues (such as the sound of a failing motor) or visible signs (like discoloration and melted insulation).

Technological Advances in Diagnostics

The evolution of digital technology in the mid-20th century marked a significant breakthrough. The introduction of digital multimeters, oscilloscopes, and microprocessor-based diagnostic devices revolutionised the approach to maintenance. Electrical fault detection transitioned from subjective assessments to objective, quantifiable scrutiny. This period saw the inception of error code systems where measurable parameters could be encoded into standardised messages. Over time, these systems evolved from simple analogue displays to sophisticated diagnostic platforms capable of integrating with computerised maintenance management systems (CMMS).

Contemporary Practices

In modern property maintenance, fault diagnosis error codes are generated by highly sophisticated systems that blend real-time sensor monitoring with machine learning algorithms. These systems are integrated into smart building technologies, providing uninterrupted oversight and immediate alerts when anomalies are detected. The contemporary approach not only enhances the speed and accuracy of fault detection but also supports predictive maintenance strategies. Historical data gathered from error codes is stored and analysed, allowing maintenance teams to identify patterns and trends that influence future upkeep decisions.

Concept and Description

Core Principles and Mechanisms

Fault diagnosis error codes operate on a set of principles that combine electrical measurements with algorithmic analysis:

- Continuous Monitoring: Sensors embedded in electrical systems continuously capture data such as voltage, current, and temperature.

- Threshold Comparison: Each measured parameter is compared against predefined thresholds that represent normal operating conditions. When a measurement falls outside these thresholds, an anomaly is noted.

- Error Encoding: The diagnostic system translates the detected anomaly into a code, which may include qualifiers that describe the type and severity of the fault.

- Data Interpretation: These codes, when reviewed by maintenance personnel, provide clear indications of the nature of the fault. In many systems, a code might specify if the fault is related to overheating, electrical imbalances, or connectivity issues.

Classification of Electrical Faults

Electrical faults can be broadly classified into several distinct types, each of which is typically associated with specific error codes:

- Overheating: Occurs when components such as resistors, transformers, or wiring operate beyond their thermal thresholds, often due to insufficient cooling or overloading. Overheating faults are a precursor to more severe failures and can increase the risk of fire hazards.

- Short Circuits: These faults are characterised by an unintended path that allows electricity to flow with little or no resistance. Such conditions result in an excessive flow of current that can damage equipment and potentially lead to electrical fires.

- Open Circuits: An open circuit occurs when there is a break in the electrical pathway, thereby interrupting the flow of current entirely. Such faults can result in non-functional circuits and may indicate dislodged wires or faulty connections.

- Intermittent Faults: Some faults may not be constant; they occur sporadically and can be elusive in traditional testing methodologies. Intermittent faults require sophisticated data logging and temporal analysis to accurately capture, classify, and resolve.

Diagnostic Criteria

The development of accurate fault diagnosis error codes depends on stringent diagnostic criteria:

- Threshold Settings: Parameters such as voltage, current, and temperature have specific threshold values that, when exceeded, trigger the generation of an error code.

- Signal Integrity Checks: To avoid false positives, diagnostic systems employ multiple sensors and redundant data collection measures.

- Temporal Stability: Many systems require that an anomaly persists for a defined period before an error code is generated, thereby filtering out transient fluctuations.

- Comparative Analysis: Modern diagnostic algorithms compare data against historical performance records to determine whether observed deviations are significant.

These criteria assure that fault diagnosis error codes are a reliable indicator of both current system performance and potential future failures.

Functionality, Purpose, and Applications

Diagnostic Tools and Methods

Fault diagnosis error codes are identified and interpreted using a suite of advanced diagnostic instruments:

- Digital Multimeters: These devices measure electrical parameters such as voltage, current, and resistance accurately, providing immediate insight into circuit behaviour.

- Oscilloscopes: By visualising electrical waveforms, oscilloscopes help detect transient anomalies, allowing technicians to observe momentary fluctuations that may be indicative of underlying issues.

- Smart Testers: Embedded with microprocessors, these testers are capable of running complex self-diagnostic routines. They automatically generate error codes by comparing real-time data with preset conditions.

- Advanced Sensors: Modern installations may also employ sensors that continuously monitor operational parameters and provide immediate alerts when irregularities occur.

Together, these diagnostic tools form a comprehensive system that supports both rapid detection and in-depth troubleshooting of electrical faults.

Repair Procedures and Corrective Measures

Once an error code has been generated, maintenance teams use the associated information to guide corrective actions. The typical procedures include:

- Rewiring: For issues related to faulty or degraded wiring, a complete or partial rewiring of the affected circuit is often necessary to restore proper functionality.

- Component Replacement: In cases where specific components, such as breakers or sensors, have failed, the replacement of these parts is essential to ensure system reliability.

- Socket and Switch Repairs: Minor faults involving defective sockets or switches can usually be remedied with targeted repairs. This may involve reseating connections or replacing worn-out components.

- Calibration and Re-testing: Post-repair, diagnostic devices are recalibrated and retested to ensure that the fault has been effectively resolved.

- Documentation: Each repair action is carefully documented in maintenance logs, which serve as reference points for future diagnostics and compliance audits.

These measures are critical for restoring the proper function of electrical systems and preventing recurring issues.

Preventive Maintenance Integration

preventive maintenance strategies leverage fault diagnosis error codes to establish a proactive approach to system upkeep:

- Scheduled Inspections: Regular inspections using digital diagnostic tools help to identify early warning signs of electrical faults before they evolve into significant issues.

- Maintenance Checklists: Detailed checklists that incorporate error code interpretation criteria ensure that routine maintenance can systematically address underlying issues.

- Data-Driven Predictive Maintenance: Historical error code data is analysed to predict potential failures, enabling technicians to schedule repairs during planned downtimes rather than reactive emergency repairs.

- Continuous Monitoring Systems: Integrating IoT-enabled sensors into property maintenance systems allows for real-time monitoring, ensuring that deviations from normal performance are addressed immediately.

Through these practices, fault diagnosis error codes not only facilitate immediate troubleshooting but also contribute to long-term efficiency and reliability in property maintenance.

Classifications and Variants

Fault diagnosis error codes exhibit a range of variants, each corresponding to specific system designs and detection methodologies:

- Analogue Error Codes: In earlier diagnostic systems, error codes were primarily analogue signals represented by varying voltage or resistance levels. These required manual interpretation and were prone to subjective assessment.

- Digital Error Codes: With technological advancement, digital systems now generate clear, discrete codes that can be easily interpreted by both technicians and automated management systems. These codes are characteristically more precise and less prone to misinterpretation.

- Hybrid Systems: Some modern fault diagnosis systems merge both analogue signalling and digital encoding to leverage the benefits of each method. Such systems provide real-time data along with historical context, ensuring a robust diagnostic process.

- Vendor-Specific Codes: Different manufacturers may implement proprietary error code systems tailored to their unique diagnostic equipment. While these can vary in format, they generally conform to industry standards regarding severity and fault classification.

Understanding these variants is crucial for maintenance teams, as it influences both the selection of diagnostic tools and the interpretation of the generated data.

Systems, Tools, and Methodologies

Diagnostic Instrumentation

Modern fault diagnosis is underpinned by an array of specialised instruments:

- Digital Multimeters and Oscilloscopes: These remain the bedrock of electrical testing, with a focus on speed and accuracy. Their advanced models often include logging capabilities that record transient events.

- Smart Testers: These devices incorporate sophisticated microprocessors that automate the diagnostic process. Smart testers are capable of remote monitoring and can generate detailed error reports that are integrated into centralised maintenance systems.

- Integrated Sensors: In many large-scale installations, sensors continuously monitor electrical performance. These sensors feed data into centralised management systems, which use machine learning algorithms for predictive analysis.

Each of these instruments is selected based on its ability to provide reliable, repeatable measurements that form the basis for sound diagnostic conclusions.

Standard Protocols

Fault diagnosis error codes are generated and interpreted in alignment with rigorous standards and protocols:

- BS7671 Standards: These British Standards provide comprehensive guidelines for the safe installation and operation of electrical systems. They assist in defining thresholds and acceptable variances for various electrical parameters.

- Electrical Installation Condition Reports (EICR): Regular EICR reports document the condition of electrical installations and detail any faults identified during routine inspections.

- HSE Guidelines: The Health and Safety Executive issues guidelines that ensure electrical maintenance practices adhere to nationally recognised safety benchmarks.

- Regulatory Compliance: These standards ensure that the methodologies used for fault detection and diagnosis are not only technically robust but also legally compliant.

The application of these standardised protocols guarantees that the diagnostic process is systematic, universally comprehensible, and legally defensible.

Technological Integrations

Recent developments in technology have introduced new layers of capability to fault diagnosis:

- IoT Integration: Internet-of-Things (IoT) devices have revolutionised diagnostic processes by enabling real-time monitoring and remote data transmission. Such integrations allow for continuous oversight without the need for manual intervention.

- Predictive Analytics: Advanced algorithms analyse historical fault data to predict future failures. This integration of predictive maintenance helps avert emergencies by scheduling repairs before faults evolve into critical issues.

- Cloud-Based Data Management: Centralised data repositories allow maintenance teams to analyse trends over time. Cloud-based solutions facilitate efficient sharing of diagnostic data with remote experts, ensuring that complex faults are addressed swiftly.

These integrations not only enhance diagnostic accuracy but also improve the overall responsiveness and efficiency of maintenance operations.

Stakeholders and Entities Involved

Fault diagnosis error codes form an integral part of the property maintenance ecosystem, influencing a network of stakeholders:

- Property Owners and Landlords: These stakeholders rely on accurate diagnostics to maintain the value and safety of their assets. For organisations managing multiple properties, such as All Services 4U, precise error codes are essential in coordinating large-scale maintenance efforts.

- Maintenance Technicians: Technicians employ diagnostic tools to interpret error codes, guiding them toward the appropriate repair methods. Their expertise is vital for translating abstract fault codes into tangible maintenance actions.

- Regulatory Bodies: Agencies responsible for enforcing electrical safety, such as the HSE and local building authorities, use diagnostic data to ensure compliance with relevant codes and standards.

- Equipment Manufacturers: Companies that produce diagnostic instruments and smart sensors play a crucial role in continually advancing the technology behind fault detection.

- Facilities Managers: In larger commercial or institutional settings, facilities managers coordinate routine maintenance schedules and manage the integration of diagnostic systems into comprehensive property management programmes.

This collaborative network ensures that fault diagnosis error codes are effectively leveraged to promote a safe and well-maintained built environment.

Legal, Regulatory, and Ethical Considerations

The implementation and interpretation of fault diagnosis error codes are subject to stringent legal and regulatory frameworks:

- Compliance with Electrical Codes: Standards such as BS7671 establish the parameters for safe electrical installations. These codes dictate the acceptable ranges for key electrical measurements and set benchmarks for fault detection systems.

- EICR Requirements: The mandatory completion of Electrical Installation Condition Reports ensures that properties are regularly inspected and that any detected faults are documented and remedied in a timely manner.

- Health and Safety Regulations: Compliance with HSE guidelines ensures that all maintenance practices prioritise the safety of both residents and maintenance personnel. These regulations are designed to minimise risk and prevent hazardous situations.

- Ethical Considerations: Maintenance with fault diagnosis error codes must balance economic efficiency with the imperative to safeguard human life and property. Transparent reporting and accountability are critical to uphold ethical standards in maintenance practices.

- Data Privacy and Security: As diagnostic systems increasingly integrate with IoT devices and cloud technologies, ensuring the security of sensitive diagnostic data becomes paramount. Adequate measures must be taken to protect data integrity and confidentiality.

By aligning diagnostic practices with these legal and ethical frameworks, property maintenance operations can achieve a high degree of safety, reliability, and public trust.

Performance Metrics and Data

The success and efficiency of fault diagnosis systems are often measured using various performance metrics:

- Diagnostic Accuracy: This metric assesses the ability of a fault diagnosis system to correctly identify electrical anomalies and accurately classify them according to severity.

- Response Time: The time lag between the detection of a fault and the initiation of corrective measures is critical, particularly in high-risk scenarios.

- System Reliability: Long-term reliability, measured through the frequency of recurring faults and the stability of diagnostic outputs, is a key indicator of system performance.

- Maintenance Efficiency: This evaluates how effectively fault diagnosis error codes contribute to the reduction of emergency repairs and unanticipated downtime.

- Cost Savings: Financial metrics track the reduction in repair costs and operational expenses attributed to proactive maintenance strategies informed by diagnostic codes.

- User Satisfaction: Feedback from property managers and maintenance technicians is used informally to gauge the effectiveness and ease of use of diagnostic systems.

A table summarising these metrics might be structured as follows:

| Metric | Description | Measurement Approach |

|---|---|---|

| Diagnostic Accuracy | Percentage of correctly identified faults | Comparative analysis against manual inspections |

| Response Time | Time taken to initiate repairs after detection | Time-stamped data logs |

| System Reliability | Frequency and recurrence of faults | Longitudinal performance data |

| Maintenance Efficiency | Reduction in emergency repair incidents | Cost analysis and downtime tracking |

| Cost Savings | Financial benefits from preventive maintenance | Comparative cost assessments |

| User Satisfaction | Feedback from maintenance personnel and property managers | Surveys and qualitative interviews |

These metrics provide a quantitative basis for assessing the performance of fault diagnosis systems and guide future improvements in diagnostic methodologies.

Challenges, Barriers, and Limitations

Despite their benefits, fault diagnosis error codes encounter a range of challenges and constraints that can impact their effectiveness:

Technical Challenges

- Sensor Calibration: Inaccurate sensors or miscalibrated devices can lead to erroneous data that may result in false positives or negatives.

- Interference: Environmental factors such as electromagnetic interference or temperature fluctuations can affect sensor readings.

- Data Integration: The integration of legacy systems with modern digital diagnostic tools often poses interoperability challenges, requiring significant retrofitting and system updates.

- Transient Faults: Intermittent or sporadic faults that do not persist long enough to trigger a stable error code can be difficult to capture accurately.

Operational Barriers

- Access Limitations: Restricted physical access to certain parts of a property may hinder thorough diagnostics, especially in older buildings or complex infrastructure.

- Variability in Technician Expertise: Differences in the skill levels of technicians can lead to inconsistent interpretations of error codes and subsequent repair actions.

- Resource Constraints: Small property management teams may lack the advanced diagnostic instruments needed to perform high-quality diagnostics, leading to reliance on manual methods.

Economic Considerations

- Initial Investment: The cost of purchasing and maintaining advanced diagnostic tools and sensors can be prohibitive for some organisations.

- Ongoing Maintenance Costs: Regular calibration, software updates, and system upgrades require continuous investment.

- Cost-Benefit Dilemmas: Balancing the cost of implementing advanced systems against the benefits derived from increased reliability and reduced emergency repairs is a persistent challenge.

Conceptual and Methodological Limitations

- Ambiguity in Error Codes: Some error codes may be ambiguous, representing multiple potential issues without providing specific guidance, which can complicate the diagnosis process.

- Standardisation Issues: Variability in error code formats and interpretations across different manufacturers may hinder the establishment of uniform diagnostic practices.

- Predictive Limitations: While data-driven and predictive analytics have advanced, forecasting intermittent or emergent faults with absolute certainty remains challenging.

Addressing these barriers requires continuous research, technological innovation, and adaptive maintenance strategies to ensure that fault diagnosis error codes remain a reliable component of property maintenance.

Impact, Influence, and Legacy

The implementation of fault diagnosis error codes has significantly transformed property maintenance practices over the years. Their influence can be observed in several key aspects:

Safety Improvements

- Early Fault Detection: By identifying issues at an early stage, these diagnostic systems help prevent major electrical failures, thereby reducing the incidence of fires and other hazards.

- Improved Response Times: The immediate alerts prompted by error codes enable faster isolation of potential risks, helping to safeguard both occupants and maintenance personnel.

- Enhanced Compliance: Fault diagnosis facilitates consistent adherence to industry standards and regulatory requirements, ensuring that properties remain safe and legally compliant.

Economic Benefits

- Cost Reduction: The early identification of faults allows for preventive maintenance that can mitigate the need for expensive emergency repairs.

- Reduced Downtime: Efficient fault management minimises the downtime associated with unexpected failures, thereby enhancing operational continuity.

- Long-Term Value: Consistent maintenance and the use of diagnostic data contribute to the prolonged lifespan of electrical installations, which in turn supports higher property valuations.

Standardisation and Industry Evolution

- Unified Diagnostics: The widespread adoption of error codes has led to the standardisation of troubleshooting methods across the property maintenance sector.

- Benchmarking: Historical diagnostic data has provided benchmarks for performance and reliability, influencing the evolution of best practices.

- Innovation Catalyst: The integration of advanced diagnostics, such as smart sensor networks and IoT devices, continues to drive innovation in maintenance practices.

Legacy in Maintenance Systems

- Data-Driven Decision Making: The extensive data generated by diagnostic systems has paved the way for predictive maintenance models that not only react to faults but anticipate them.

- Continuous Improvement: The iterative feedback provided by fault diagnosis fosters a culture of continuous improvement in maintenance protocols, ensuring that systems evolve in line with emerging technological advancements.

- Influence on Regulatory Standards: Diagnostic practices have influenced the development and refinement of regulatory standards, ensuring that maintenance operations remain effective and safe.

Future Directions, Cultural Relevance, and Design Discourse

Technological Forecasting and Innovations

Emerging advanced diagnostic systems are poised to revolutionise fault diagnosis through the integration of predictive analytics and machine learning. As sensor technology continues to improve, the accuracy and reliability of diagnostic data will increase, enabling even more effective predictive maintenance strategies. The convergence of cloud computing, IoT, and sophisticated data analytics promises a future where fault diagnosis error codes are not only generated automatically but are also interpreted in the context of historical trends and predictive models. This integration will facilitate proactive maintenance, significantly reducing downtime and mitigating risks.

Emerging Maintenance Protocols

The notion of preventive maintenance is gaining ground, driven by nuanced interpretations of fault diagnosis error codes. Future protocols may incorporate dynamic response strategies, where maintenance schedules are automatically adjusted based on continuous real-time data and predictive analytics. By aligning maintenance tasks with actual system performance, property managers and technicians can transition from a reactive to a predictive paradigm. These evolving protocols will likely incorporate automated alerts, detailed performance logs, and adaptive scheduling techniques, providing a more efficient and responsive maintenance framework.

Potential Regulatory Developments

As fault diagnosis systems become increasingly sophisticated, regulatory frameworks will likely evolve to accommodate new technologies. Future revisions of standards such as BS7671 and guidance from regulatory bodies like the HSE may introduce stricter diagnostic criteria and more granular reporting requirements. These developments will ensure that diagnostic systems are not only technologically advanced but also uphold the highest levels of safety and reliability. The ongoing dialogue between industry-leading diagnostic technology and regulatory oversight promises to create a robust framework that benefits property managers, technicians, and occupants alike.

Cultural and Design Implications

The integration of advanced diagnostics into property maintenance practices has broader cultural and design implications. As smart technologies become ubiquitous, the design of properties may increasingly accommodate considerations for integrated diagnostic tools, modular wiring, and accessible sensor placements. This evolution will affect architectural design and property management, emphasising the importance of creating environments that are both efficient and adaptable. The cultural shift towards data-driven maintenance is redefining industry norms, encouraging a focus on sustainability, resilience, and continuous improvement. In this way, fault diagnosis error codes influence not just technical operations but also the aesthetic and functional design of modern properties.

Convergence of Predictive Maintenance and User Experience

As diagnostic systems advance, the convergence between technical precision and intuitive user experience will become more pronounced. Sophisticated predictive maintenance systems will not only generate data but also transform it into actionable insights that are accessible to both technically oriented personnel and non-specialist stakeholders. The resultant improvements in responsiveness and safety will have a profound impact on property management practices, ensuring that every fault code, whether minor or severe, is addressed efficiently. This evolution represents a significant step toward creating a maintenance ecosystem that is not only safe and efficient but also user-centric and forward-thinking.

Continued Evolution and Industry Impact

The trajectory of fault diagnosis technology is one of continuous evolution, driven by both technological breakthroughs and practical operational needs. As research in sensor technology, data analytics, and machine learning progresses, the future may witness diagnostic systems capable of near real-time fault predictions. This capability will enable maintenance teams to preemptively address issues long before they manifest as significant hazards. The legacy of current systems, therefore, is not static; it forms the foundation upon which future innovations will build, ensuring that property maintenance remains a dynamic, data-driven field with profound implications for safety, efficiency, and overall property value.