Inside A Gas Safety Inspection What Engineers Check

Inside A Gas Safety Inspection What Engineers Check

Why Are Gas Safety Inspections Essential for Every Property?

A gas safety inspection isn’t just another line on your compliance checklist—it’s the frontline defence against hidden dangers that can jeopardise lives, property value, and your reputation for taking care of your people. If your property has a gas supply, this annual inspection keeps you in step with UK law and ahead of the kinds of risks that don’t make a sound until something’s already gone wrong.

You never regret proactive safety—only the disaster that comes from skipping it.

Let’s call it what it is: gas safety isn’t paperwork for its own sake. That certificate proves you’ve met your legal responsibilities, but it’s also proof you don’t cut corners when it counts. Without this, you might be out of compliance, invalidating insurance, risking tenancy disputes, and even opening the door to prosecution under the Gas Safety (Installation and Use) Regulations 1998. More importantly, it’s the single strongest way to shield your property from emergencies nobody wants to face—leaks, carbon monoxide, or faulty appliances.

The problem is silent: a neglected boiler or invisible gas leak rarely gives warning. Risk builds up quietly, sometimes for months, before making trouble absolutely unavoidable. That’s why brokers, landlords, developers, and facilities managers who sleep soundly at night see an annual gas safety check as an undisputed minimum—for peace of mind, for compliance, and for the security of everyone who relies on that property being safe.

Gas safety isn’t a checkbox; it’s a statement about what kind of professional you are.

Who Must Get Gas Safety Checks, and What’s At Stake If You Don’t?

Let’s be 100% clear: if you own, manage, or control property with a gas supply in the UK—whether it’s a single home, a high-rise block, commercial office space, or a portfolio of lets—you are responsible for ensuring a current, valid Gas Safety Certificate is in place. No exceptions, no ‘I thought someone else handled it’, no waivers for empty properties.

The real risk isn’t gas—it’s assuming compliance is someone else’s problem.

Precisely who’s on the hook?

- Private and social landlords: Houses, flats, HMOs, social housing, and yes—short-term lets and holiday Airbnbs.

- Managing agents, facilities, or site controllers: Anyone running space with a gas connection.

- Commercial property operators: Schools, care homes, shops, restaurants, and offices, regardless of size.

- Shared buildings: Communal boilers, kitchens, or water heaters fall squarely under duty-holder rules.

If you’re uncertain, assume you’re responsible. Even an unused appliance means an active legal obligation remains.

What happens if this slips through the cracks? Official fines often start at £6,000 per breach, but the true cost is heavier: cancelled insurance, voided tenancy agreements, legal claims, and potentially criminal prosecution if harm follows. trusted industry sources confirm that regulatory enforcement is intensive, with most penalties coming when routine documentation is missing, outdated, or inaccurate.

Then there’s your reputation. One failed inspection can mean years of diminished trust with tenants, letting agents, and commercial partners. Gas safety isn’t only about preventing worst-case scenarios—it’s about protecting every line in your compliance ledger from being rewritten overnight.

Liability is retroactive; compliance is your only real protection.

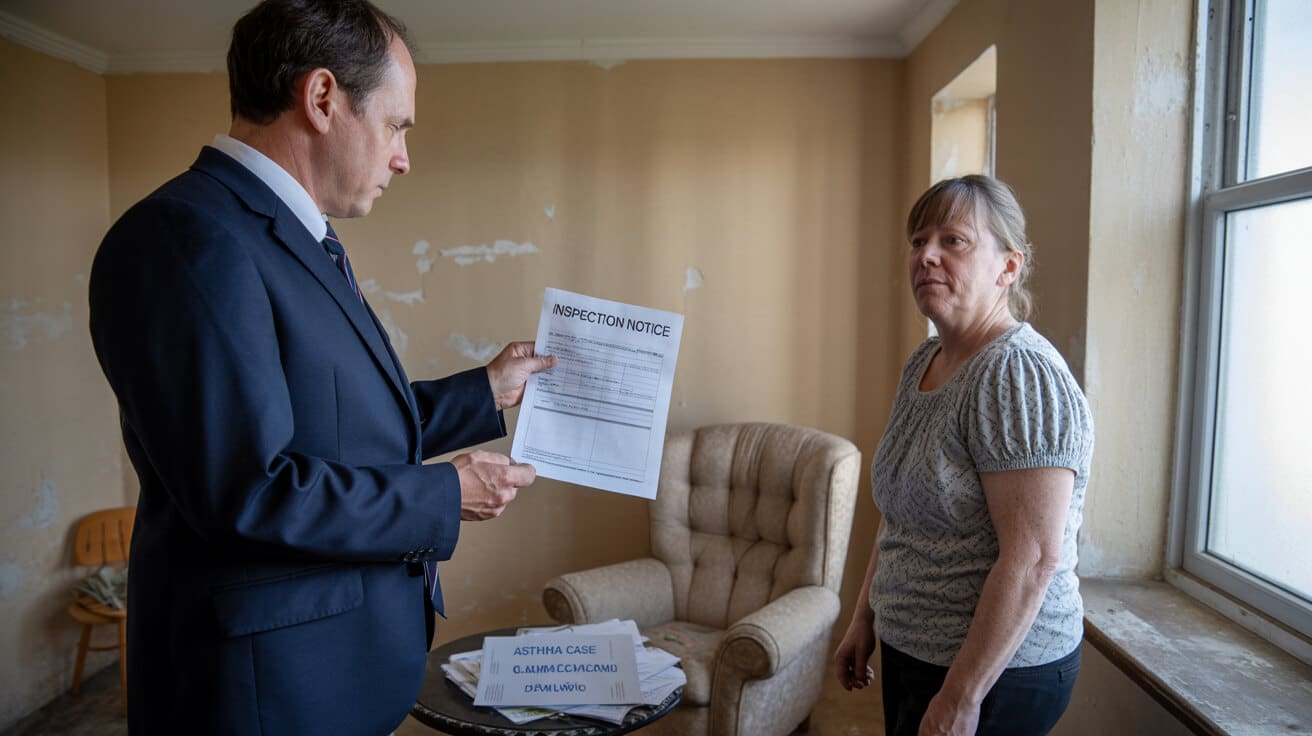

What Exactly Does a Gas Safety Inspection Cover?

A professional gas safety inspection is a methodical deep-dive—not a cursory look—with each step logged for records and proof, should any part of your property’s compliance ever be questioned. Certified Gas Safe engineers don’t just tick off boxes; they test, validate, and document, so you’re covered front-to-back.

The difference between safety and risk is as simple as the inspection trail you can prove.

Core elements checked in every visit:

- Full appliance logging: Gas boilers, cookers, and heat sources are catalogued and referenced against prior service records for continuity.

- Visual and installation integrity: Is everything correct, undamaged, and professionally installed? DIY fixes and unapproved modifications are flagged.

- Functionality test: Systems are run at full operation—engineers check ignition, flame pattern, and performance of every critical feature.

- Gas tightness and leak search: Using sensitive calibrated metres, pipework and valves are pressure-tested; even micro-leaks are traced.

- Ventilation & flue assessment: Ensuring airflow is free, blockages/non-compliant venting found, combustion by-products safely discharged.

- Combustion and efficiency verification: Special instruments measure flue gases; results cross-checked with manufacturer specs.

- Information labelling and recording: Proper signage, operating instructions, and compliance tags must be clear and present. No gaps.

If there are multiple appliances or a plant room, each element is checked individually—no banana skins left behind. Any issue that would prevent certification is logged, explained, and mapped out for next steps.

Once complete, your gas safety certificate isn’t just a formality. It’s an audit-proof track record of diligence and good management.

How Do Engineers Detect Risks Beyond a Simple Visual Check?

What separates a professional inspection from the “DIY” version? Certified engineers bring both diagnostic kit and expertise, able to unearth dangers that amateur eyes never spot. They don’t rely on luck or a quick glance; every risk gets rooted out, documented, and explained to you without jargon.

The worst threats are the ones you can’t see—but an engineer’s process is designed to catch them anyway.

Under the hood—what they really check:

- Pipework condition and tracing: Even pipe runs hidden in walls or under floors are surveyed for corrosion, mechanical strain, or poor support.

- Valve and regulator operation: Shut-off, emergency cut-offs, and regulators are functionally tested; failing mechanism means immediate action.

- Advanced flame examination: Engineers assess the intensity, colour, and stability of all flames—not just for looks, but as a safety indicator.

- Pressure and manufacturer conformity: Instrument readings for pressure and gas throughput are matched to the precise spec—no guesses or hand-waving.

- Safety equipment: Checks on thermostats, CO alarms, and interlock devices. If any device is out of date or missing—instant fail.

This thoroughness includes specific attention to conversions, recently renovated spaces, outbuildings, and even garden offices—anywhere with gas piping or appliances, DIY works, or signs of wear.

Each finding is logged, with photographic evidence or readings where necessary. Your compliance file now has proof that every risk was checked by a competent person. If an authority or tenant challenges your diligence, you have more than just words backing up your claim.

Why Are Flue and Vent Checks a Non-Negotiable Part of Gas Safety?

The most catastrophic gas-related incidents—especially those involving carbon monoxide—begin not with an appliance, but with poor ventilation or blocked flues that go unchecked. Forgetting or skipping this step is the root cause of tragic, preventable loss.

Almost all carbon monoxide events can be traced to simple airflow mistakes—ones an engineer would catch in a minute.

The essentials of vent and flue testing:

- Vent presence and clearance: Every required vent must be open, visible, and unobstructed—no blocked grills or painted-over ducts.

- Flue pathway survey: Engineers use tools and smoke tests to confirm continuity—looking for cracks, blocked sections, and secure fittings in every length of flue.

- Airflow adequacy: All gas appliances require defined airflow; using formulae and live checks, the engineer calibrates for worst-case (multiple devices in use).

- Alarm testing and renewal: carbon monoxide detectors are checked for working batteries and expiration (it’s a common miss!), and replaced if found wanting.

Industry data consistently shows that statistically, the absence of these checks magnifies risk and legal exposure—far beyond the cost or hassle of getting them done. Owners who prioritise this step seldom find themselves on the wrong end of a complaint or insurance claim.

How Is Leak and Pressure Testing Conducted to Maximum Safety Standards?

Engineers treat gas leak and pressure checks as their top security priorities—because an undetected fault, no matter how “minor”, will eventually become a major repair, a callout, or even a crisis.

Little cracks turn into lawsuits. Pressure drops don’t fix themselves.

Professional-grade leak detection in action:

- Electronic leak detectors: These sniff out even the tiniest gas release around joints, pipes, and appliances—including spots you can’t usually inspect.

- System pressure tests: Using a manometer, the system is monitored for any drop beyond allowable tolerances—a move that triggers a stepwise leak search.

- Soap solution sweeps: Where suspicion arises, engineers paint on solution to expose pinhole leaks missed by metres.

- Combustion analysis: Tools monitor by-products to reveal failure points or non-obvious inefficiencies.

- Documented remediation: Each result, fix, and re-test is recorded for your compliance file—no “handshake deals”.

Rather than a single-diagnostic event, this approach spots invisible issues early—ensuring tenants, residents, or businesses aren’t exposed to risk. Any reading outside UK code triggers warnings and a halt until verified repairs bring the system back to safety.

What If Your Property Fails or Receives an Advisory on Gas Safety?

No property owner enjoys a fail or “advisory” on their gas inspection. Still, compliance is about facing up to the issues—not ignoring, delegating, or hiding them. The longer you leave advisory faults or failures untreated, the deeper your risk and liability.

Ignoring an advisory isn’t clever savings—it’s choosing future emergency over a straightforward fix.

What is the workflow when there’s a problem?

- Passed (green light): Your appliances are safe and legally documented; you move forward with letting or operations—no flags.

- Advisory noted: Engineers note issues that are “pass for now” but will escalate if not rectified soon—think wear, minor leaks, or ageing detectors. These will reappear, and worse, in next year’s check.

- Fail (unsafe): System is disconnected. You must arrange for a repair, retest, and fresh certificate before returning to use.

Reputable engineers supply you with a digital certificate, annotated PDF with risks flagged, and photographic evidence supporting every finding (Gas Safe Register). The upside is clarity: no “bluffing” or finger-pointing—just a clear, actionable picture of what needs fixing and when.

Resolving findings as soon as possible closes the risk window, preserves your insurance, and places you firmly in the “responsible manager” category in the eyes of tenants and auditors alike.

How Do You Ensure Compliance and Save Time Managing Gas Safety?

Staying compliant isn’t about firefighting at the last minute—it’s about making reliable compliance almost automatic. Smart portfolio owners and facilities managers use systems, automation, and the right service partners to keep on top of obligations—without sacrificing time or mindshare.

The cost of messy compliance is more than a fine; it’s operational headaches and lost trust.

Practical workflows for modern compliance:

- Instant digital certificates: Certificates arrive paperless and secure, ready for instant sharing or upload to your property management app.

- Automatic reminders: No more missed renewals or chasing up expiry dates—ahead-of-time alerts keep you in step.

- Portfolio summarisation: Central dashboards put dozens of addresses in front of you in minutes, not days.

- Live repair and review logs: You see the full history—every visit, quote, repair and fault—whenever needed.

- Clear communication: The best providers translate tech jargon into human explanations, recommending fix timelines and keeping you informed at every stage.

All Services 4U clients get this as standard:

- Fully qualified, DBS-checked Gas Safe engineers—backed by proven technical and compliance expertise.

- Paperless digital certificates and photographic documentation on demand.

- Responsive action on any issue, with honest recommendations and transparent pricing.

- A proactive approach—so you spend less time coordinating, and more time focusing on growth or improvement.

When compliance is painless, your team shifts from defence to progress. That’s how professionals stay ahead.

Book with All Services 4U Today

A single overlooked certificate, missed vent, or faulty appliance can flip your entire operation from “safe as houses” to exposed and at risk. Playing catch-up never ends well. The step that secures your property, your reputation, and your stakeholders is acting before risk decides to act for you.

Thousands of managers and owners choose All Services 4U to deliver reliable, compliant, and frictionless gas safety across every type of property.

Every safe property begins with one moment of action—don’t wait for risk to call your bluff.

Booking with All Services 4U gives you instant access to qualified engineers, instant digital paperwork, and support that’s as direct as it is professional. You aren’t just ticking a compliance box—you’re future-proofing your assets and proving to tenants, partners, and yourself that the safety line doesn’t get crossed.

Take decisive control—book your next gas safety inspection with All Services 4U, and make compliance the easiest box you’ll tick this year.

Frequently Asked Questions

What triggers a failed gas safety inspection even when appliances appear to work reliably?

Most failed gas safety inspections stem from silent, easy-to-overlook issues rather than the obvious malfunction of appliances. The common culprits are subtle gas leaks at pipe joints, ageing seals, missing documentation, unlabelled system upgrades, or expired carbon monoxide detectors—none of which may affect daily operation but all of which break compliance.

Inspections often catch problems invisible to the casual eye or nose: a hairline pipe crack, a sensor battery low, or a vent that’s been painted shut during prior works. It’s not rare for a perfectly functional boiler to trigger a red flag when legacy appliances aren’t officially decommissioned or the associated paperwork is out of date. The law asks for more than visible safety—it requires a complete, traceable system, down to every label and record.

Real safety is what gets tested, documented, and proven—not just what works when you flick the switch.

Hidden reasons for non-compliance that property owners miss

- Tiny, undetectable leaks that only appear in a pressure decay (“tightness”) test.

- Appliances not in use but not formally removed from gas service lists.

- Insufficiently vented rooms—even a closed grille or blocked chimney can fail an otherwise safe system.

- DIY changes on valves, pipes, or connectors that were never signed off.

- Compliance stickers or manuals that have gone missing after refurbishment or tenant changes.

What changes in regulation have made inspections stricter?

Regulatory updates over the last two years have cracked down on “paper asset” and dormant-appliance loopholes. Documentation errors now count as serious as mechanical defects, and councils or insurers can downgrade your property’s compliance if a single backup heater or non-commissioned cooker remains unlogged (HSE annual report, 2023).

Having a skilled, multi-trade team like All Services 4U catch and fix these hidden faults ahead of inspection is the practical way to stay one step ahead. Owners who wait for something obvious to break often end up paying double: once for the emergency call-out, and again for the compliance penalty.

How do professional gas engineers uncover risks that tenants or landlords routinely overlook?

Professional gas engineers rely on a blend of hands-on checks, calibrated tools, and regulatory knowledge to surface faults no one else notices. The process covers a lot more than seeing (or smelling) a leak: it involves tightly sequenced tests, verification of every system component, and digital evidence collection.

Specialist equipment, like manometers and flue gas analysers, allows engineers to spot pressure drops, faulty combustion, or subpar venting—none of which give warning until they’re measured. Engineers trace pipe runs for hidden corrosion, stress, or vibration marks. Even small details like a label’s presence or the correct installation sequence of a valve gets checked, since non-compliance in these “invisible” spots is a leading reason for failed audits.

The right tool, handled by the right expert, is the difference between assumed safety and proven safety.

Why isn’t a “no smell, no flames” home check enough?

Many leaks are too tiny for human senses to catch, but they linger and accumulate, especially in closed spaces or communal systems. Amateur fixes, loose connections from older appliances, and blocked vents can all pass the “smell test”—until they don’t. Undiagnosed, these risks stack up and threaten tenancy, insurance, or property value.

What digital methods do All Services 4U engineers use?

Every check is logged with photos, digital signatures, and time stamps for a robust compliance trail. This creates defensible evidence if an incident ever leads to an insurance dispute or a council audit. For portfolio or HMO owners, these records provide a transparent, up-to-the-minute asset safety map.

Which overlooked systems put your gas safety record—or tenancy—at risk?

It’s easy to focus on boilers or cookers, but it’s the supporting infrastructure and shared components that most often result in compliance failures. Backup heaters in communal spaces, old capped outlets, inaccessible metre housings, or off-map pipework can tank your record—not because they actively fail, but because they aren’t properly logged and checked.

Uninspected areas, like plant rooms in HMOs or backups left after upgrades, often “inherit” non-compliance from past owners or contractors. Metre boxes behind locked service cupboards are out of sight, out of mind—until your audit depends on access. Modern multi-unit blocks are now subject to new rules that split safety responsibility across all stakeholders, making communication and coordination a higher priority.

The compliance risk you can’t see is usually the one waiting to surprise you on audit day.

What are the most frequent “blind spots” in recent enforcement actions?

- Shared or communal gas installations not scheduled for inspection alongside private appliances.

- Old gas fires, wall heaters, or cookers left after refurb but not formally capped or documented.

- Pipes rerouted through nonstandard extensions, adding undocumented joints or materials.

- Blocked or altered external venting, sometimes caused by building works or tenant modifications.

Enforcement data from 2024 shows penalties for missing CO alarms and uncapped secondary assets doubled compared to prior years (Gas Safe Register, Q1 2024). All Services 4U’s coordinated “asset sweep” and documentation approach is designed to address these vulnerabilities before they become compliance headaches.

How should property owners and managers prepare for a clean inspection on complex sites?

Preparation means more than surface tidying—it’s about access, documentation, system readiness, and tenant communication, especially in complex settings like HMOs or commercial sites. The biggest failures come from missing keys, unchecked sensors, or forgotten shared spaces.

Sending clear, early inspection notice to every building occupant prevents last-minute clashes or missed rooms. Keeping digital logs for all historical gas works or certificates ensures inspectors aren’t left waiting or forced to downgrade compliance based on missing paperwork.

Every small gap in preparation—be it an inaccessible plant room or an untested CO alarm—becomes an audit risk for every resident, not just one.

Checklist for audit-proof inspection readiness

- Advance notice to all occupants and staff, including instructions to provide access at specific times.

- Verified location and operating status of every CO and smoke detector—including in vacant, seasonal, or low-use areas.

- Print or digital compilation of historical certificates, manuals, and remedial works.

- Minor fixes, like vent clearing or dormant appliance capping, scheduled and completed at least a week prior to inspection.

How does All Services 4U simplify compliance preparation?

Our digital dashboard syncs reminders for both tenants and managers, logs all service events, and coordinates repair windows—minimising missed opportunities for a pass. Especially in estates or multi-audit scenarios, this single-source approach prevents the domino effect of one missed task jeopardising the whole property’s safety record.

Which digital platforms and processes have transformed gas safety compliance for landlords and facilities teams?

Cloud-based compliance platforms and integration between property management apps and safety certification have changed the landscape for proactive property managers. Automated reminders, geotagged photo uploads, and a consolidated audit trail mean landlords no longer risk losing a certificate, missing a renewal date, or failing a surprise inspection.

Tablets and smartphones now serve as mobile compliance hubs, capturing every inspection in real time. Digital trackers allow managers of large portfolios to view the status of every property and every asset, instantly. Tenants also benefit: with self-serve dashboards, occupants see evidence of compliance and receive automatic updates.

A lost paper certificate can cost a tenancy—real-time, cloud-stored safety records secure every asset, every time.

What core features do modern compliance systems provide?

- Unified, secure storage for all gas safety certificates, manuals, and repair logs—accessible anywhere.

- Digital signatures and geo-tagged reporting, directly tied to asset inventory and renewal scheduling.

- Portfolio views for organisations, landlords, or facilities leads handling dozens of units.

- Automated scheduling for both inspections and remedial works, reducing the risk of “forgotten” assets.

- Backward-proof traceability, providing legal and reputational cover during disputes or audits.

All Services 4U partners with leading compliance platforms to ensure that nothing gets overlooked and every inspection, repair, or certificate is logged, time-stamped, and audit-ready on demand.

What are the risks of last-minute, bargain gas safety inspections—and how does proactive support protect your reputation?

Last-minute or cut-price inspections often turn out to be short-term “savings” that create long-term consequences. These rushed jobs can skip critical but invisible checks, lack evidence or photo documentation, and sometimes send non-certified staff—resulting in invalid certificates and costly follow-up audits.

An incomplete record doesn’t just put your property at risk—it can trigger insurance denials or council action. If a compliance issue surfaces within a certificate’s window and the documentation falls short, the entire claim or tenancy can collapse retroactively.

True value is in confidence—you can’t shortcut your way to a clean compliance record or lasting peace of mind.

How do premium, proactive inspections differ from the cheapest offerings?

- Certified engineers conduct exhaustive asset checks, digital records, and photo evidence for every visit.

- Reminders are sent ahead of renewal deadlines, avoiding compliance gaps or frantic last-day calls.

- All venting, dormant assets, sensors, and secondary systems are inspected and documented—never skipped for speed.

- Ongoing advice and scheduling support helps keep your safety record audit-ready year-round.

- Only properly credentialed professionals—no unsupervised trainees or generalists—are sent to site.

With All Services 4U, you’re not just fulfilling a legal duty—you’re protecting your properties, tenants, and reputation in a way that pays off at every renewal and audit. Choose resilience, not just compliance.