What are the legal requirements for electrical safety inspections

What are the legal requirements for electrical safety inspections

Understanding Electrical Safety Inspection Mandates

Electrical safety inspections are a critical component of property maintenance, ensuring the safety of occupants and compliance with legal standards. As a property owner or business operator, you’re required to understand and adhere to several key regulations.

Legal Basis for Electrical Installation Condition Reports (EICR)

The Electrical Installation Condition Report (EICR) is a document mandated by law to assess the safety of electrical installations. It is a requirement under the Electricity at Work Regulations 1989, which stipulates that electrical systems must be maintained to prevent danger.

Impact of Portable Appliance Testing (PAT) Regulations

Portable Appliance Testing (PAT) is governed by the Health and Safety at Work Act. PAT regulations require business owners to ensure electrical appliances are safe and do not pose a risk to employees or customers. The frequency of PAT varies based on the type of appliance and its use but is generally guided by a risk-based approach.

Compliance with BS 7671 Wiring Regulations

BS 7671, also known as the Wiring Regulations, provides technical standards for electrical installations. Compliance with these regulations is essential for the safety and functionality of your property’s electrical systems. Skilled professionals must execute these standards to ensure consensus and compliance with the Wiring Regulations Advisory Group (WRAG).

Adherence to Specific Legal Citations

Property owners must be aware of specific legal citations that govern electrical safety, such as the Electricity at Work Regulations 1989. These regulations set the framework for electrical safety and the legal responsibilities of property owners to prevent electrical hazards.

Landlord and Business Owner Obligations for Electrical Safety

As a landlord or business owner, you are legally obligated to ensure the electrical installations in your properties are safe and well-maintained. This responsibility extends to both fixed installations and portable appliances.

Frequency of Safety Inspections

You must arrange for regular Electrical Installation Condition Reports (EICR) to be conducted by a qualified person. The standard interval for these inspections is every five years, but this may vary depending on the property type and usage.

Required Documentation for Compliance

To demonstrate compliance with electrical safety laws, you must keep up-to-date documentation, including the EICR, records of any remedial work carried out, and Portable Appliance Testing (PAT) reports.

Guidance from the Health and Safety Executive (HSE)

The Health and Safety Executive (HSE) provides comprehensive guidance on fulfilling your legal duties. This includes adhering to the Electricity at Work Regulations 1989 and implementing a risk-based approach to maintenance, as recommended by HSE.

By meeting these obligations, you not only comply with the law but also ensure the safety of your tenants and the integrity of your property.

Enforcement Powers of Local Housing Authorities

Local Housing Authorities (LHAs) play a pivotal role in ensuring electrical safety compliance within their jurisdictions. They are endowed with enforcement powers to issue remedial notices to property owners who fail to comply with electrical safety standards.

Impact of Remedial Notices on Property Owners

When a property fails to meet the required electrical safety standards, LHAs can issue remedial notices that mandate property owners to carry out necessary repairs or improvements within a specified timeframe, typically 28 days. Failure to comply with these notices can lead to further legal action.

Penalties for Non-Compliance

Non-compliance with electrical safety standards can result in significant penalties, including financial fines. In severe cases, LHAs have the authority to prohibit the use of the property until it meets the safety requirements.

Alignment with National Standards

Local regulations must align with national standards, such as the 18th edition of the Wiring Regulations. However, LHAs may have additional protocols or requirements based on local housing policies. Property owners are advised to familiarise themselves with both sets of regulations to ensure full compliance.

Qualifications for Competent Electrical Inspectors

When it comes to electrical safety inspections, the qualifications of the inspector are paramount. A competent person should possess a thorough understanding of electrical systems and the potential hazards associated with them.

Verifying Inspector Credentials

To verify an inspector’s credentials, you should request evidence of their qualifications and check their registration with recognised industry bodies such as SELECT, NICEIC, or NAPIT. These organisations maintain registers of qualified inspectors who are authorised to conduct electrical safety assessments.

Registration with Professional Bodies

Registration with professional bodies ensures that inspectors are up-to-date with the latest safety standards and practices. It is essential that the inspector is registered with a scheme that validates their competence and adherence to industry regulations.

Influence of the 18th Edition of the Wiring Regulations

The 18th edition of the Wiring Regulations is the benchmark for electrical safety and compliance. Inspectors must be well-versed in these regulations to ensure that all inspections and subsequent reports meet the current legal and safety standards.

Financial Penalties for Electrical Safety Non-Compliance

Non-compliance with electrical safety regulations can lead to substantial financial penalties for property owners. These penalties are not only punitive but also serve as a deterrent to ensure adherence to safety standards.

Impact on Property Insurance

Failure to comply with electrical safety requirements can have severe implications for property insurance:

- Insurance providers may increase premiums or refuse to provide coverage.

- Claims related to electrical incidents may be denied if non-compliance is established.

Legal Consequences of Withholding an EICR

Not providing an Electrical Installation Condition Report (EICR) to tenants or authorities can result in legal actions:

- Authorities may impose fines or restrict the use of the property until compliance is achieved.

- Tenants have the right to seek legal redress, which could lead to compensation claims against the landlord.

Enforcement Actions for Non-Compliance

Persistent non-compliance can trigger enforcement actions such as Section 21 notices, which can lead to eviction proceedings. This is particularly relevant in the context of the Housing Act 1988, which stipulates the conditions under which such notices can be issued.

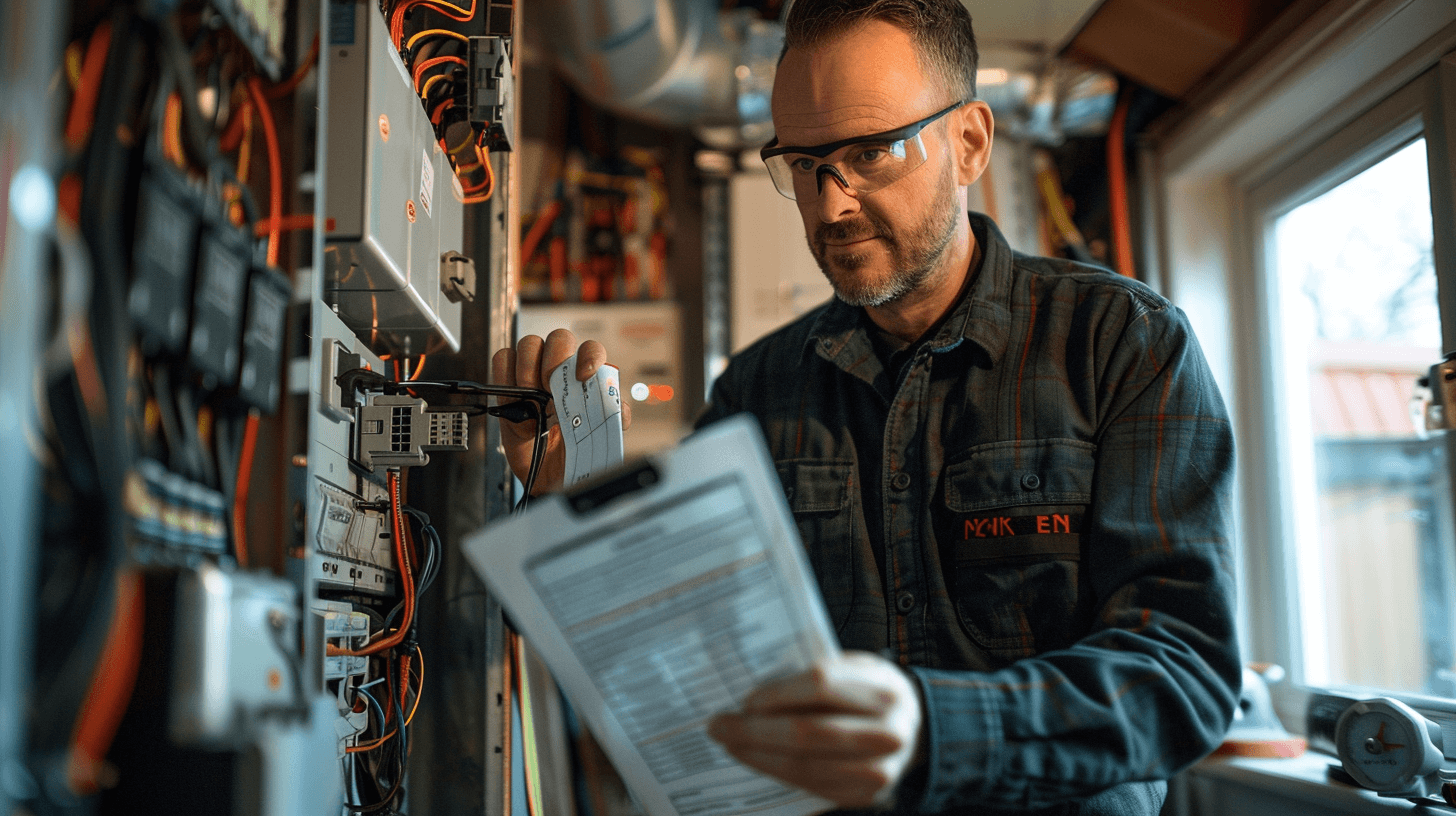

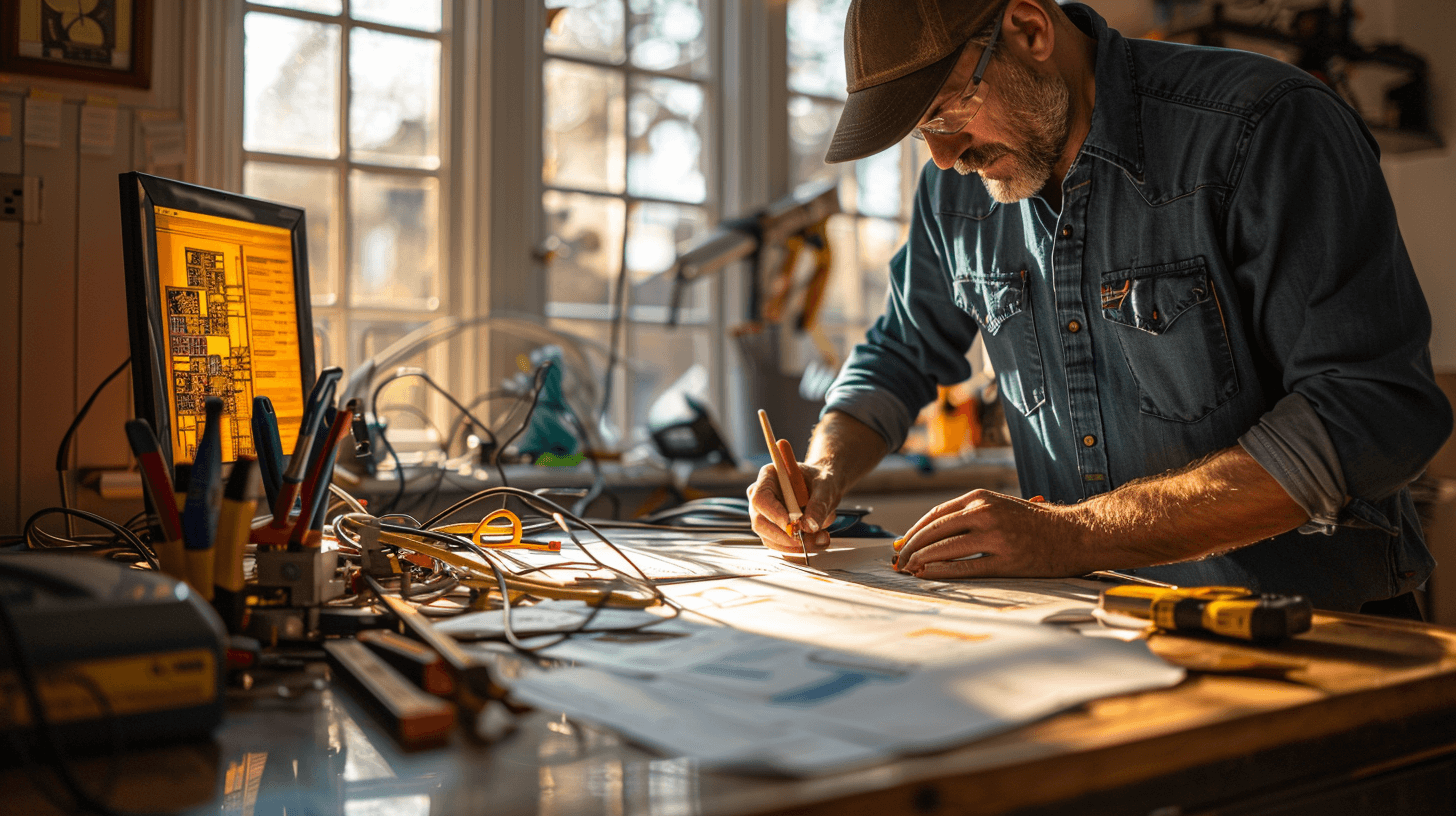

Initiating an Electrical Safety Inspection

To begin the electrical safety inspection process, property owners should take the following steps:

Scheduling the Inspection

- Contact a qualified electrical inspector registered with a Competent Person Scheme, such as SELECT, NICEIC, or NAPIT.

- Arrange a suitable time for the inspection that minimises disruption to tenants or business operations.

Determining Inspection Frequency

- Refer to the latest edition of the Wiring Regulations (BS 7671) and local housing authority guidelines to determine the recommended frequency for your property type.

- Consider factors such as the age of the electrical installation, usage patterns, and any previous electrical incidents.

Identifying Common Electrical Hazards

During an assessment, inspectors typically look for:

- Damaged or worn electrical equipment

- Overloaded circuits or power outlets

- Improperly installed or modified electrical systems

- Lack of residual current devices (RCD) protection

Ensuring Timely Remedial Work

To ensure remedial work is completed within legal timeframes:

- Obtain a detailed report from the inspector outlining necessary actions.

- Hire a certified electrician to perform the remedial work as prescribed.

- Provide the local housing authority with proof of completed work within 28 days of the inspection, if required.

Key Technical Terms in Electrical Inspections

Understanding the terminology used in electrical inspections is crucial for ensuring compliance with safety standards. Here are some essential terms and their roles in the inspection process:

Earth Bonding and Residual Current Devices (RCD)

- Earth Bonding: A safety measure that connects metallic parts of electrical installations to the earth to prevent electric shock in case of a fault.

- Residual Current Devices (RCD): Safety devices designed to instantly break an electrical circuit if a fault is detected, significantly reducing the risk of shock or fire.

Insulation Resistance and Continuity Testing

- Insulation Resistance Testing: Assesses the integrity of the insulation surrounding electrical conductors to prevent leakage currents that could lead to shocks or fires.

- Continuity Testing: Verifies that there are no breaks in the electrical circuits and that the conductors are properly connected to ensure a clear path for current flow.

Protective Device Coordination and Cable Routing

- Protective Device Coordination: Ensures that the electrical protection devices are selected and arranged to operate correctly in the event of a fault, minimising disruption and damage.

- Cable Routing: The planned path of electrical cables that must adhere to safety standards to prevent damage and maintain the integrity of the electrical system.

Comparison with International Standards

- International Electrotechnical Commission (IEC) standards often serve as a benchmark for local regulations. However, local codes may have additional requirements tailored to specific regional needs. Compliance with both sets of standards is essential for global safety and operational consistency.

Streamlining Safety Checks with Risk-Based Maintenance

Risk-based maintenance prioritises electrical safety checks based on the likelihood and potential impact of equipment failure. This approach allows for more efficient allocation of resources by focusing on areas with the highest risk, thereby streamlining the safety check process.

Debunking PAT Frequency Myths

Common misconceptions about Portable Appliance Testing (PAT) include the belief that it must be performed annually. However, the Health and Safety Executive (HSE) clarifies that the frequency of PAT should be determined by a risk assessment, not a fixed schedule.

Role of Visual Inspections in Safety Strategies

Visual inspections are a critical component of a comprehensive safety strategy. They can identify many common issues, such as damaged cables or overloaded outlets, which might not require full PAT but still pose significant risks.

HSE Guidance on Risk-Based Maintenance

The HSE provides guidance on implementing a risk-based approach to maintenance. This includes assessing the environment in which the equipment is used, the frequency of use, and the manufacturer’s recommendations, to determine the appropriate level of maintenance and testing.

Impact of Electrical Safety Compliance on Property Insurance

Electrical safety compliance is a critical factor that insurance companies consider when determining property insurance premiums. Compliance with electrical safety standards can lead to more favourable insurance terms, while non-compliance can result in increased premiums or even denial of coverage.

Non-Compliance and Property Value

Non-compliance with electrical safety regulations can adversely affect the value of your property. Potential buyers or tenants may be deterred by the increased risk and potential legal liabilities, leading to a decrease in property desirability and market value.

Environmental Considerations in Electrical Safety

Environmental sustainability is becoming increasingly important in property management. Efficient and safe electrical installations can contribute to a property’s green credentials, potentially increasing its appeal to environmentally conscious tenants or buyers.

Tenant Rights and Electrical Safety Inspections

Tenants have the right to live in a property that meets all electrical safety standards. They are entitled to request proof of compliance, such as a current EICR, and landlords must provide this documentation. Failure to meet these rights can lead to legal challenges and further implications for landlords.

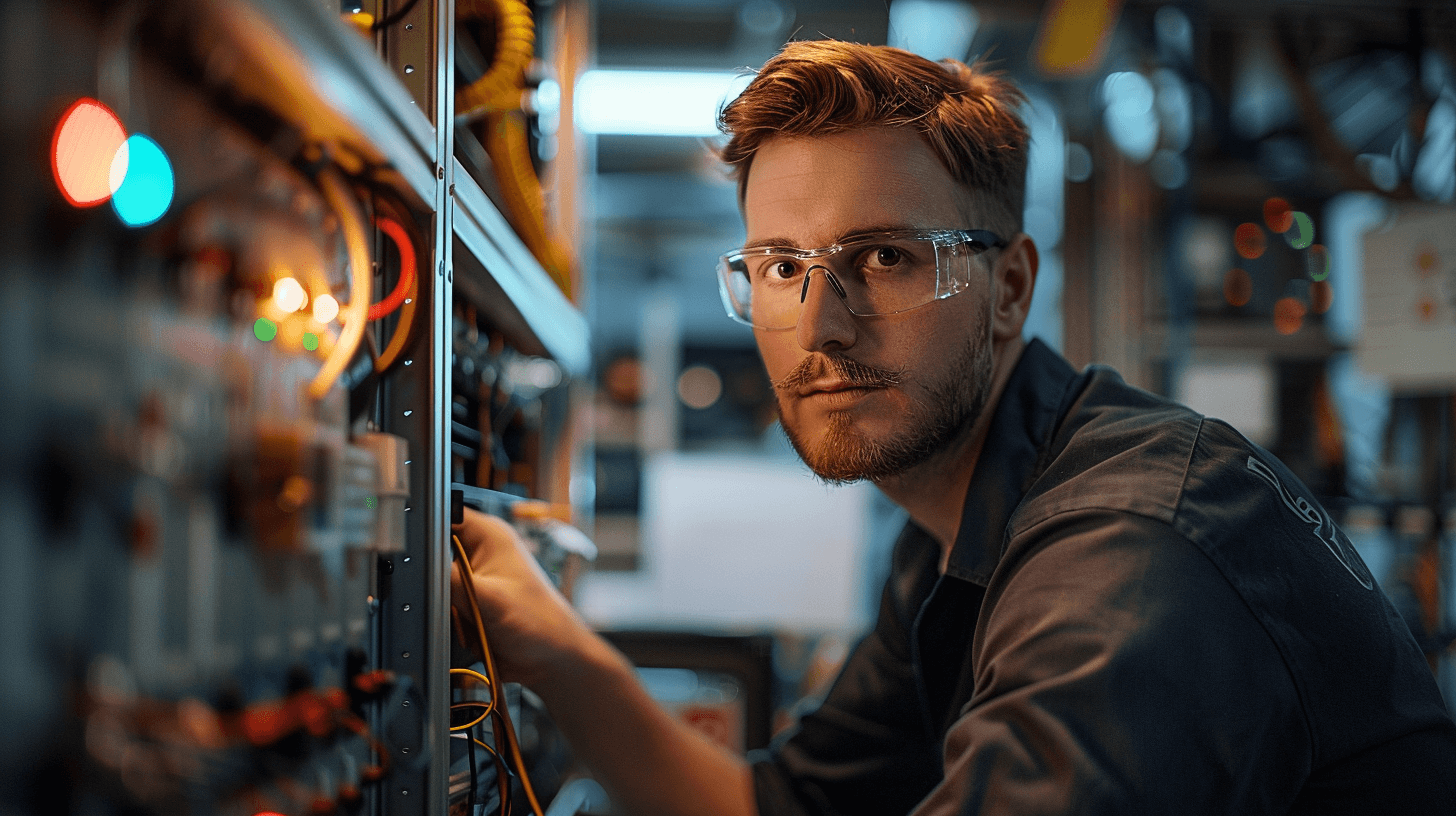

Advanced Technologies in Electrical Safety Inspections

The landscape of electrical safety inspections is continually evolving with the integration of new technologies designed to enhance accuracy and efficiency.

Innovations Enhancing Compliance and Efficiency

Innovative tools and technologies have been developed to streamline the electrical safety inspection process:

- Thermographic Cameras: Utilised to detect overheating components or connections without direct contact, allowing for early identification of potential issues.

- Smart Testing Devices: These devices automate data collection and reporting, ensuring that inspections are thorough and documentation is precise.

- Circuit Analyzers: Advanced analyzers provide detailed information on circuit load, voltage, and safety compliance, facilitating a more comprehensive inspection.

Benefits of Advanced Testing Methods

Advanced testing methods, such as thermographic inspection, offer several benefits:

- Non-Invasive Analysis: Thermography can be performed without interrupting electrical services, minimising downtime.

- Early Fault Detection: By identifying hotspots, inspectors can pinpoint potential problems before they lead to system failures.

- Enhanced Safety: These methods reduce the risk of electrical accidents during inspections by allowing for remote monitoring.

Meeting Legal Requirements with Technology

Advanced technologies support compliance with legal safety requirements by:

- Improving Accuracy: Reducing human error in inspections and testing.

- Documenting Compliance: Automated tools create detailed records that serve as evidence of compliance with electrical safety regulations.

- Facilitating Regular Maintenance: Technology enables more frequent and less intrusive inspections, aligning with legal mandates for ongoing electrical system assessments.

Role of Professional Bodies in Electrical Safety Compliance

Professional organisations play a crucial role in upholding industry standards and supporting property owners in their compliance efforts.

Contributions of Propertymark to Industry Standards

Propertymark, as a professional body, unites industry professionals and promotes a culture of integrity and professionalism. It contributes to industry standards by:

- Advocating for best practices in property management.

- Providing members with up-to-date information on legislative changes.

- Offering training and qualifications to ensure high standards of service.

Ensuring Compliance through Competent Person Schemes

Competent Person Schemes are essential for maintaining safety standards:

- They provide a framework for recognising qualified electrical inspectors.

- Membership in these schemes is often a mark of trust and competence.

- They ensure that electrical work is carried out to the standards set by the Wiring Regulations.

Membership Benefits in Professional Organisations

Membership in professional organisations aids in fulfilling legal duties by:

- Offering access to resources and guidance on compliance matters.

- Providing a network of professionals for advice and support.

- Ensuring members are informed of changes in safety regulations and standards.

Advocacy and Policy Interpretation Services

Professional bodies offer advocacy and policy interpretation services that benefit property owners by:

- Representing the industry’s interests in policy discussions.

- Clarifying the implications of new regulations for property management.

- Assisting members in navigating the complexities of compliance.

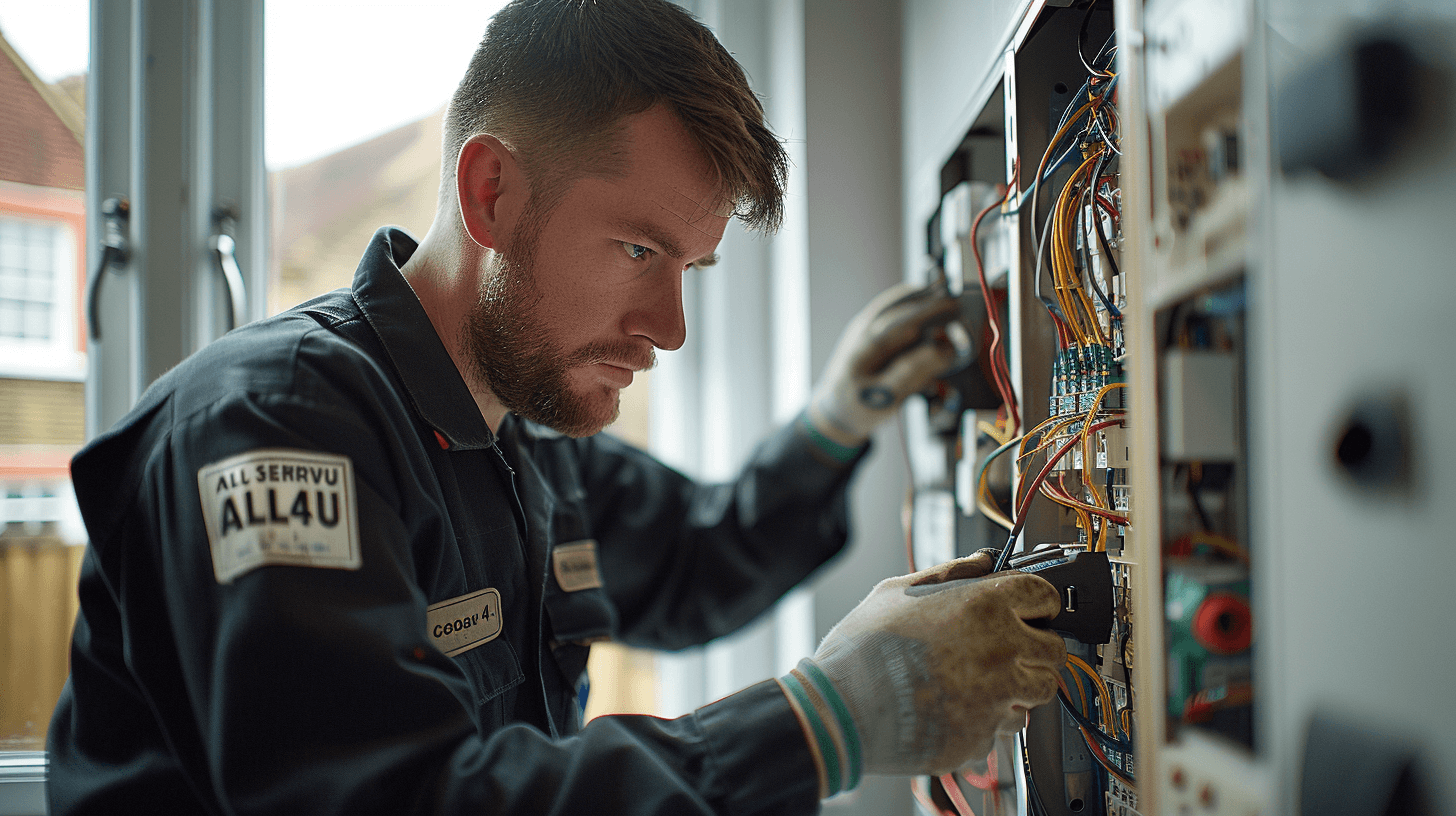

Expert Electrical Safety Services by “All Service 4U”

Ensuring Compliance with “All Service 4U”

“All Service 4U” provides comprehensive electrical safety services to ensure your property adheres to the stringent legal requirements. Their team of certified electricians specialises in:

- Conducting thorough Electrical Installation Condition Reports (EICR).

- Performing Portable Appliance Testing (PAT) in line with the Health and Safety at Work Act.

- Assessing fixed electrical equipment and installations against BS 7671 Wiring Regulations.

Comprehensive Services Offered

The services offered by “All Service 4U” encompass:

- Initial and Periodic Electrical Inspections: To identify any potential hazards and ensure ongoing compliance.

- Remedial Work: Addressing any issues found during inspections to meet legal safety standards.

- Documentation and Reporting: Providing detailed reports and certificates required for legal compliance and insurance purposes.

Staying Informed on Regulations and Standards

“All Service 4U” maintains its industry-leading position by:

- Regularly updating its practices in accordance with the latest 18th edition of the Wiring Regulations.

- Engaging in continuous professional development to stay ahead of technological advancements and regulatory changes.

Choosing “All Service 4U”

Opt for “All Service 4U” for their:

- Reliability and professionalism in delivering electrical safety inspection services.

- Commitment to meeting the legal requirements for electrical safety inspections.

- 24/7 availability to address urgent electrical safety concerns and provide emergency services.